Call Us

08045479560

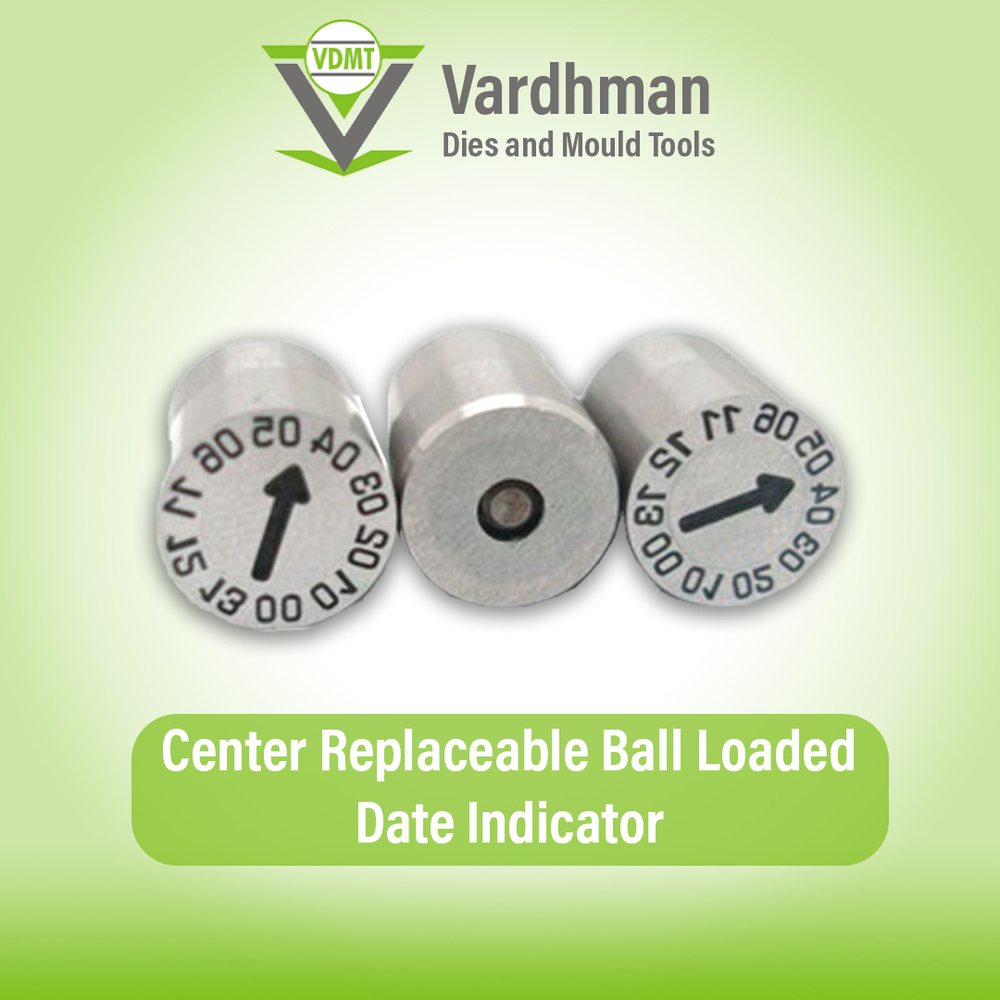

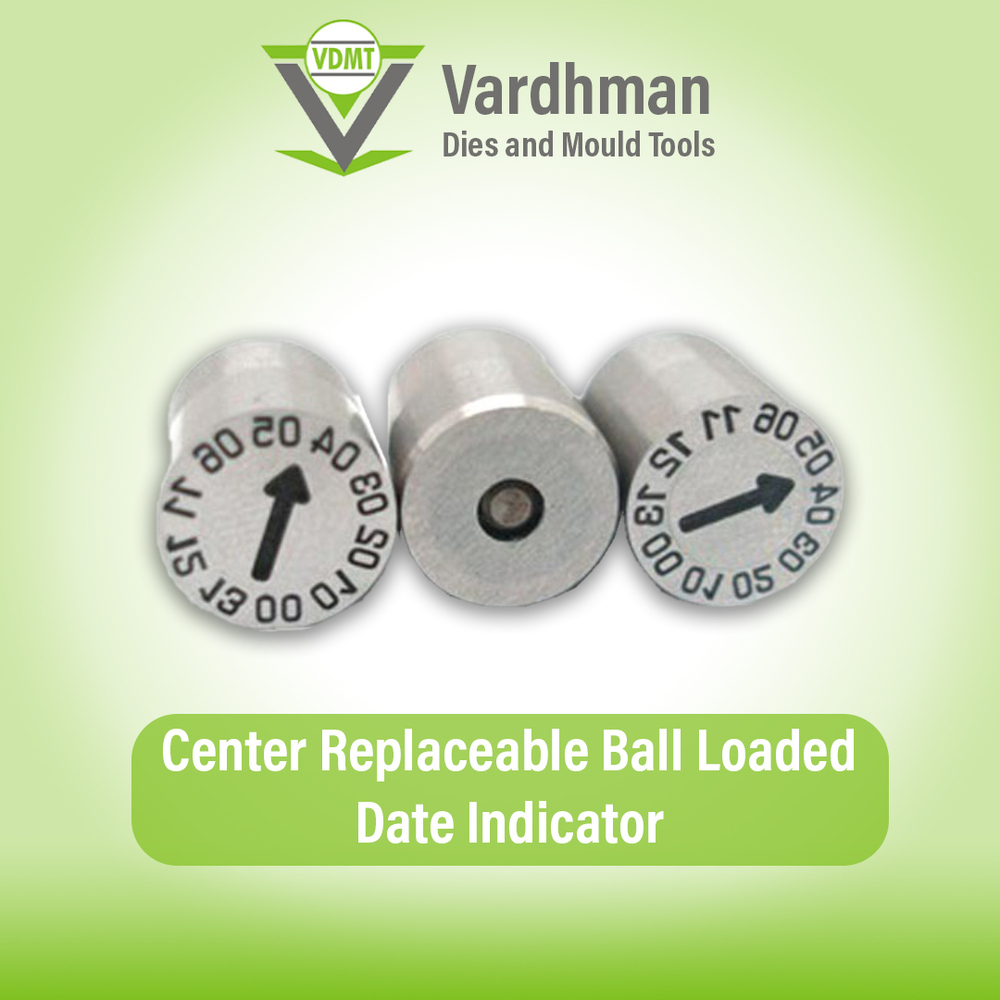

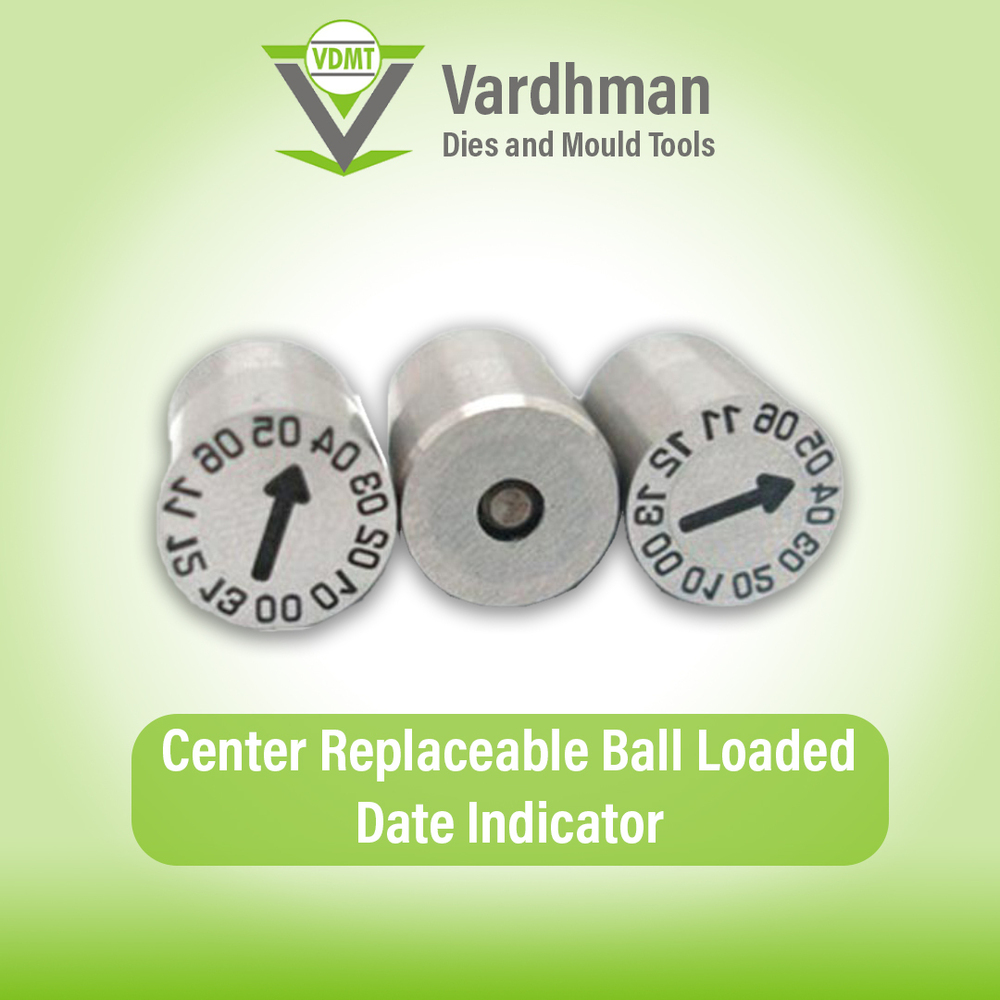

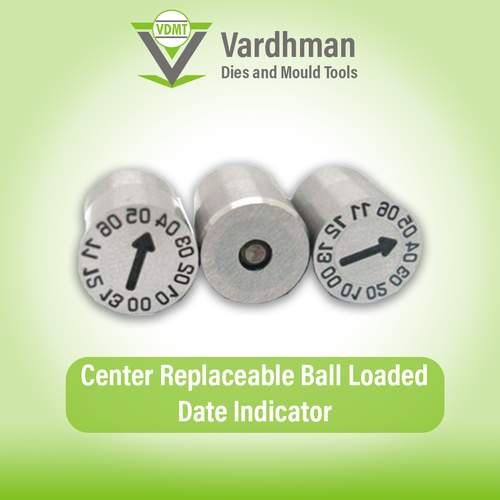

Center Replaceable Bottom Ball Loaded

800 INR/Piece

Product Details:

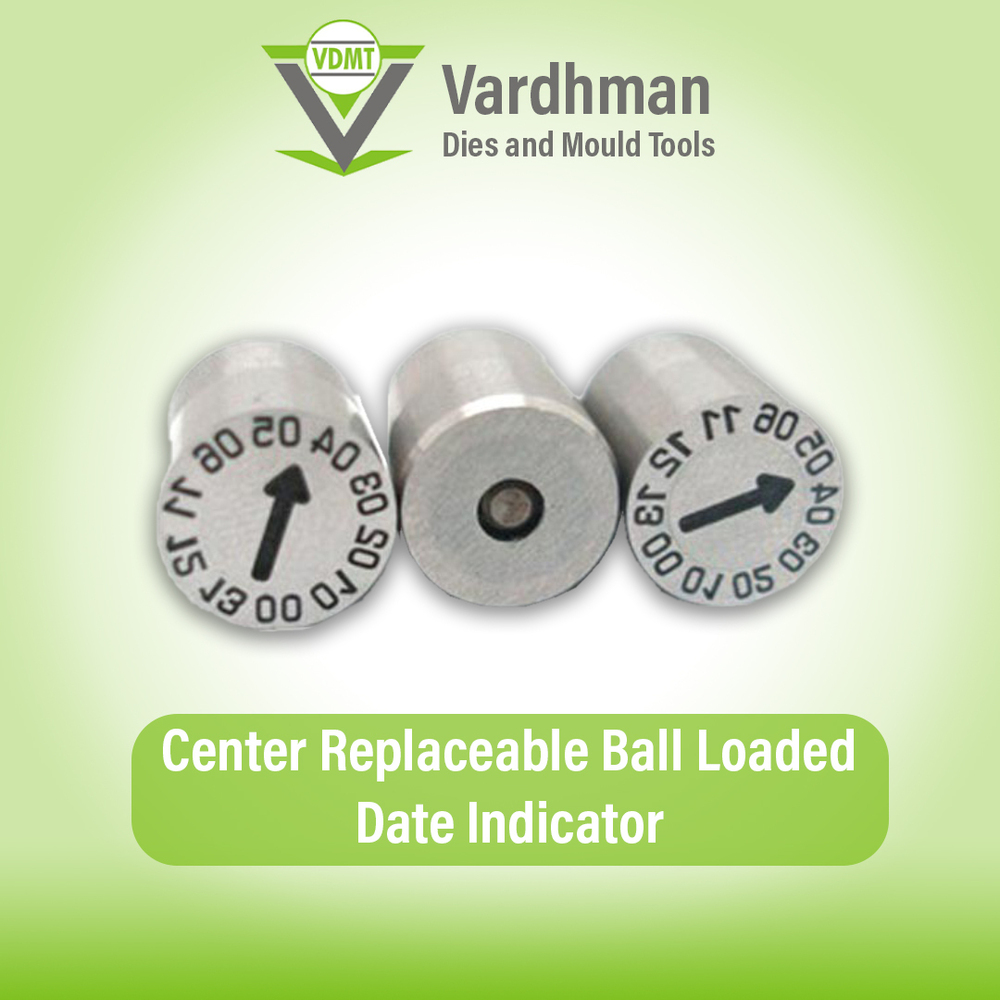

- Core Material 420, hardness: 48-52

- Usage Industries

- Material Aluminum

- Product Type Center Replaceable Bottom Ball Loaded

- Color Silver

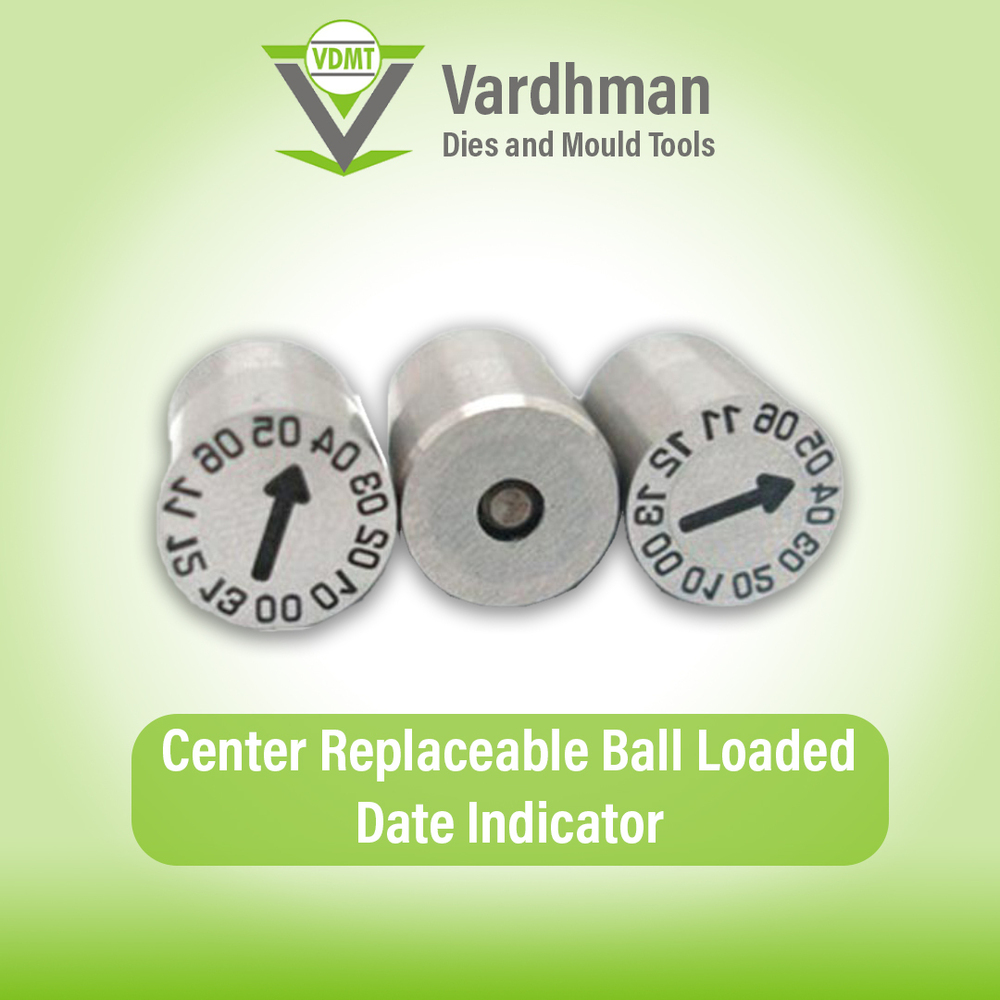

- Length 500 1000 mm Millimeter (mm)

- Warranty 1 year

- Click to View more

X

Center Replaceable Bottom Ball Loaded Price And Quantity

- 800 INR/Piece

- 10 Piece

Center Replaceable Bottom Ball Loaded Product Specifications

- 420, hardness: 48-52

- Industries

- Silver

- Center Replaceable Bottom Ball Loaded

- 500 1000 mm Millimeter (mm)

- 1 year

- Aluminum

Center Replaceable Bottom Ball Loaded Trade Information

- 1000 Piece Per Week

- 10 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

The Center Replaceable Bottom Ball Loaded is a highly efficient and durable component used in a variety of moulding and tooling applications. At Vardhman Dies & Mould Tools, we specialize in designing and manufacturing top-quality center replaceable bottom ball-loaded components that ensure smooth functionality and precision in your operations. These components are ideal for high-pressure applications and provide reliable performance in demanding industrial environments.

Key Features :

- Replaceable Bottom Ball Design: Allows for easy maintenance and replacement of the ball, extending the lifespan of the component and reducing operational downtime.

- High Durability: Constructed with high-quality materials to withstand extreme pressure and wear, ensuring long-term performance.

- Precision Engineering: Designed for precise operation and consistent functionality in various moulding processes.

- Efficient Performance: The ball-loaded mechanism allows for smooth and controlled movement, reducing friction and increasing the efficiency of the moulding process.

- Compact Design: Engineered to fit into tight spaces within moulds, making it suitable for complex moulding applications

Advantages :

- Ease of Maintenance: The replaceable bottom ball design makes it easier to maintain the component, minimizing downtime and reducing maintenance costs.

- Increased Longevity: By allowing for quick replacements of the ball, the component offers enhanced durability and a longer service life.

- Reliable Performance: Provides smooth operation, reducing the risk of malfunction or breakdown, and ensuring the consistency of the moulding process.

- Cost-Effective: Since only the ball needs to be replaced, this design lowers replacement costs compared to other types of mould components.

- Improved Productivity: The efficient performance of the component helps boost productivity by minimizing interruptions and delays in the manufacturing process.

Durable Construction for Industrial Demands

Designed with high-grade aluminum and a reinforced core, this ball-loaded bottom component withstands rigorous industry environments. Its silver finish resists corrosion, while the 48-52 hardness ensures minimal wear and tear, promising a reliable lifespan for demanding processes.

Versatile Applicability in Industrial Settings

With a variable length between 500 1000 mm, this component integrates effortlessly into diverse industrial machines. It provides consistent performance whether used for assembly lines, material handling equipment, or specialized mechanical systems. Easy replacement and adaptability make it a preferred choice.

FAQs of Center Replaceable Bottom Ball Loaded:

Q: How is the Center Replaceable Bottom Ball Loaded installed in industrial machinery?

A: The component is designed for straightforward installation, typically requiring alignment with the corresponding machine slots and securing using compatible fasteners. Detailed instructions are provided to ensure precise fitting and optimal performance.Q: What process ensures the durability and hardness of the product?

A: The product is manufactured using premium aluminum and 420-grade core material, then processed to achieve a hardness level of 48-52. This involves advanced heat treatment techniques that enhance resistance to deformation and wear.Q: When should the Center Replaceable Bottom Ball Loaded be replaced?

A: Replacement is recommended during scheduled maintenance or when there is evident wear affecting performance. Its center-replaceable design allows for easy and quick substitution without necessitating complete machine disassembly.Q: Where can I source this product in India?

A: This product is available from reputable exporters, manufacturers, suppliers, and traders located across major industrial hubs in India. You can contact these channels for bulk orders and technical support.Q: What are the primary uses of this component in industrial settings?

A: It is widely used in machinery requiring durable, load-bearing parts such as conveyor lines, automated equipment, and production systems, thanks to its flexible length and robust material properties.Q: How does the one-year warranty benefit buyers?

A: The included warranty guarantees product reliability and protection against manufacturing defects for one year from the date of purchase, providing peace of mind and support for industrial operators.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese