Call Us

08045479560

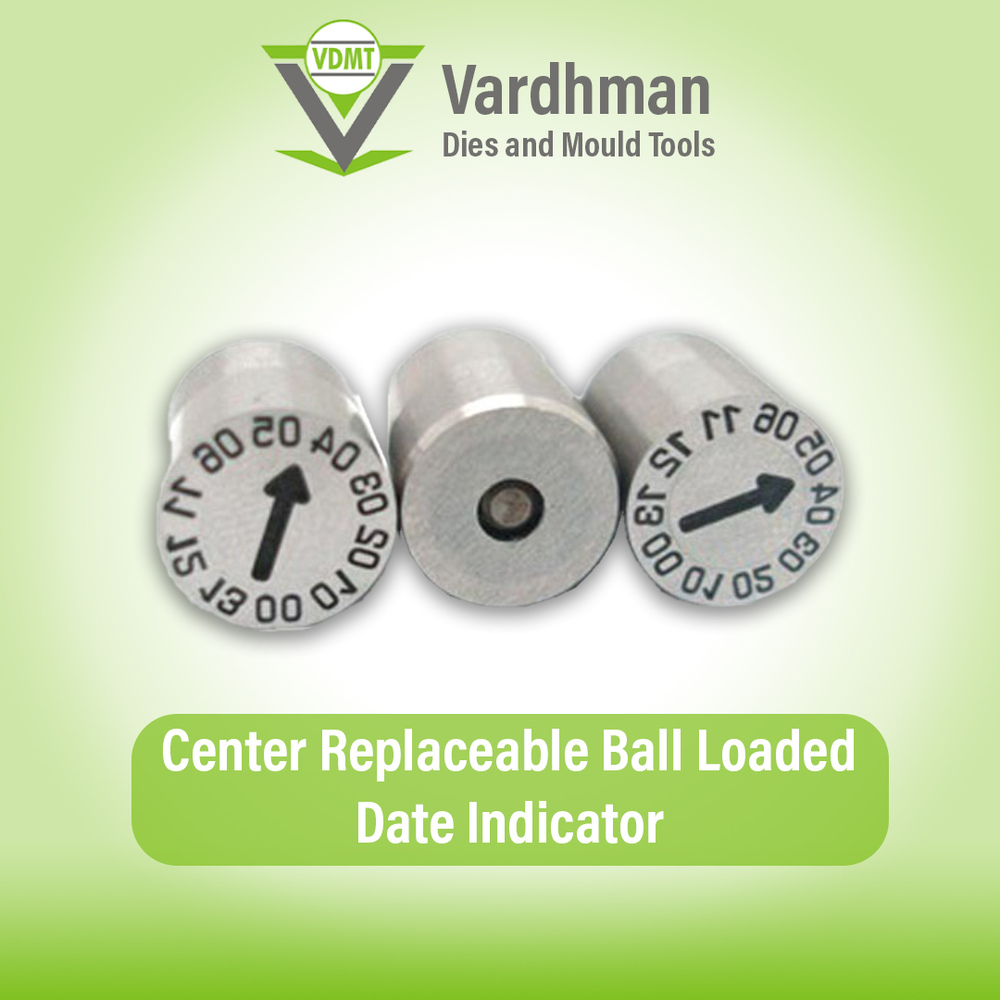

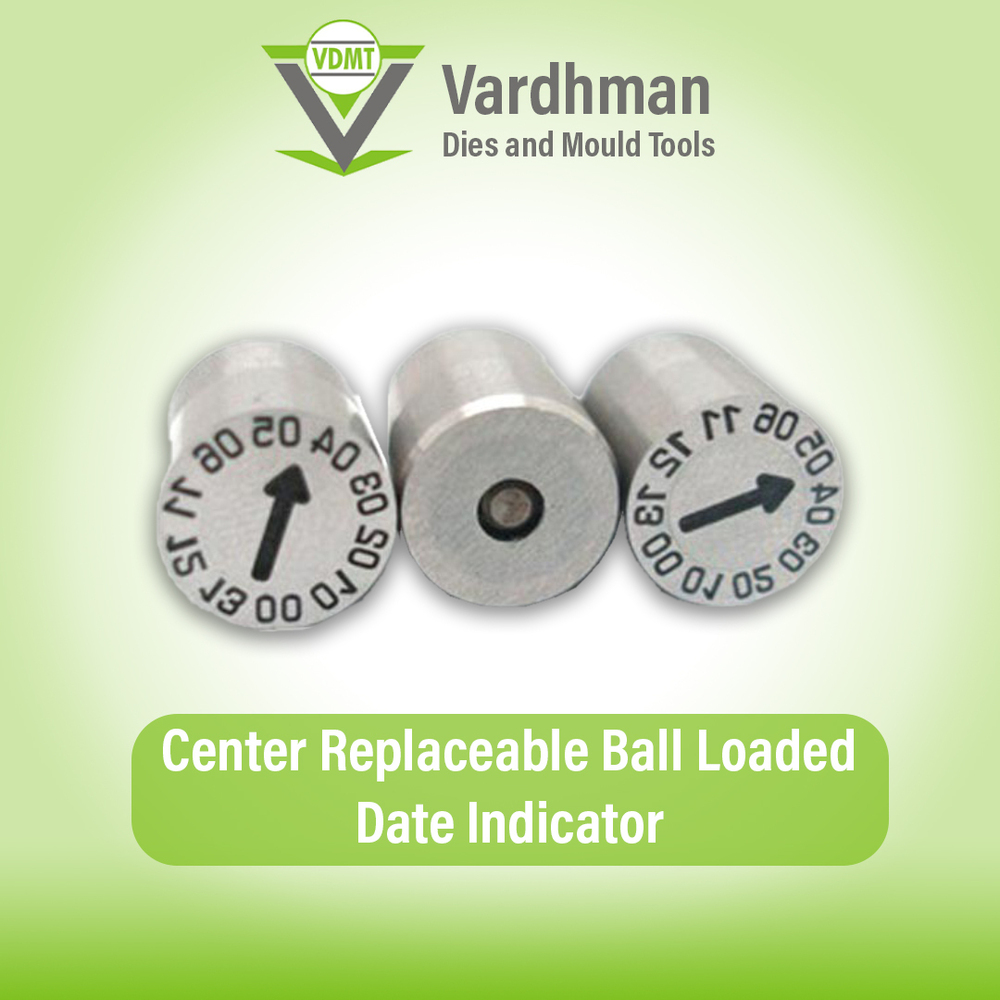

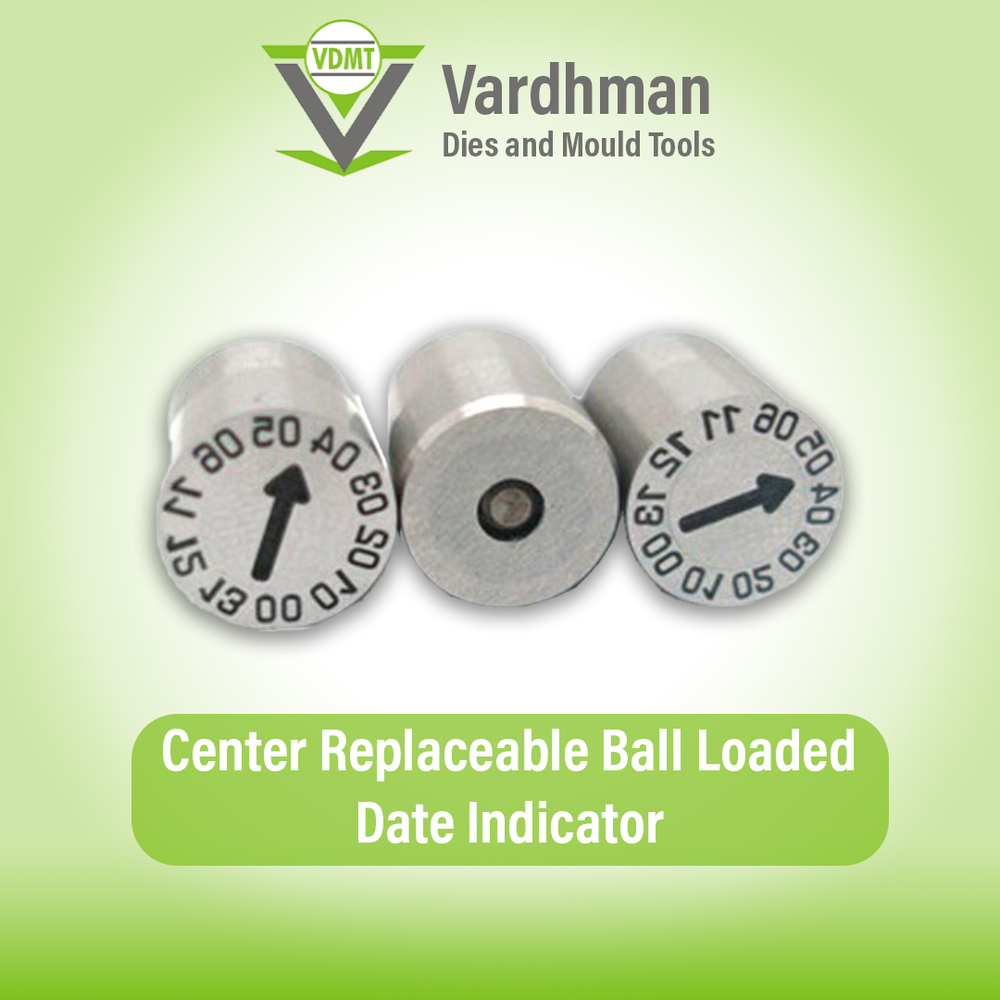

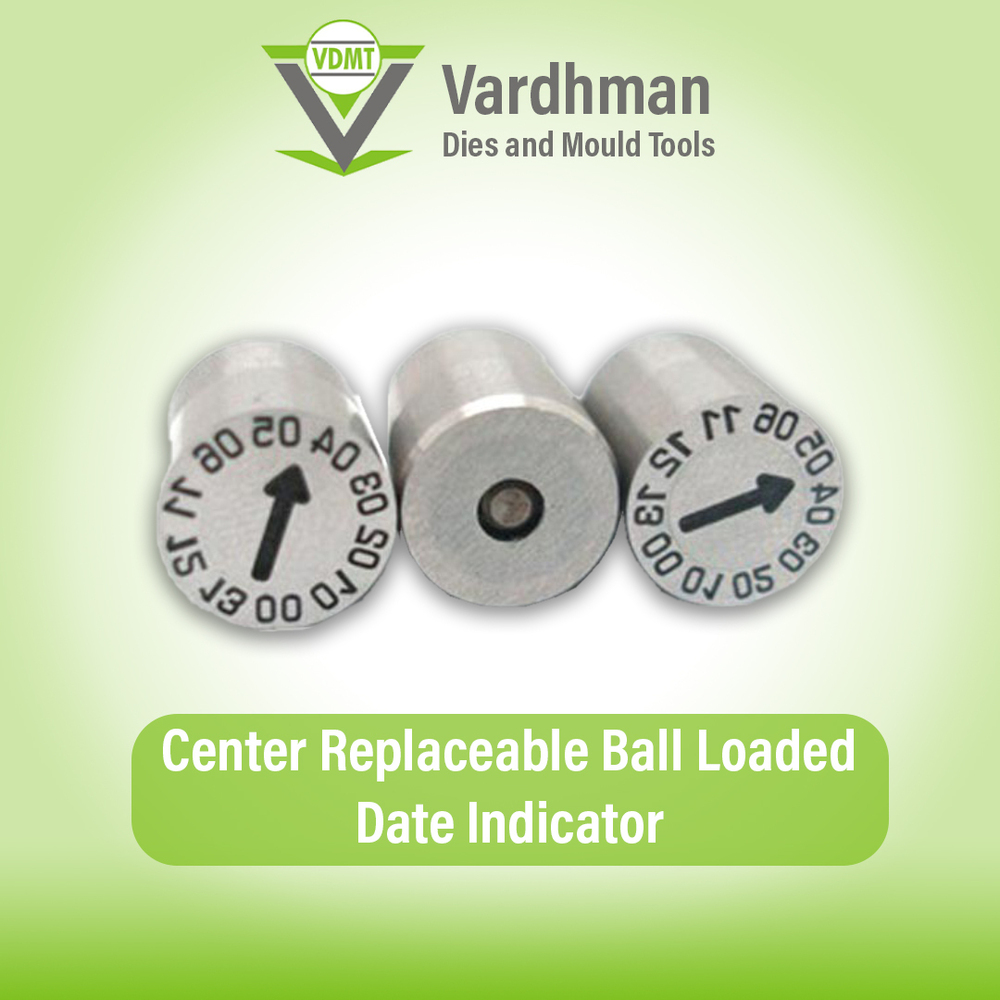

Center Replaceable Screw Type

200 INR/Piece

Product Details:

- Mould Base Mould base

- Core Material SUS - 420

- Usage Industries

- Material Aluminum

- Size Surface Finish: 0.1 micron -.04 micron

- Product Type Center Replaceable Screw Type

- Color Silver

- Click to View more

X

Center Replaceable Screw Type Price And Quantity

- 200 INR/Piece

- 10 Piece

Center Replaceable Screw Type Product Specifications

- Aluminum

- Surface Finish: 0.1 micron -.04 micron

- Industries

- 500- 1000 mm Millimeter (mm)

- 1 year

- SUS - 420

- Center Replaceable Screw Type

- Mould base

- Silver

Center Replaceable Screw Type Trade Information

- 100 Piece Per Week

- 10 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

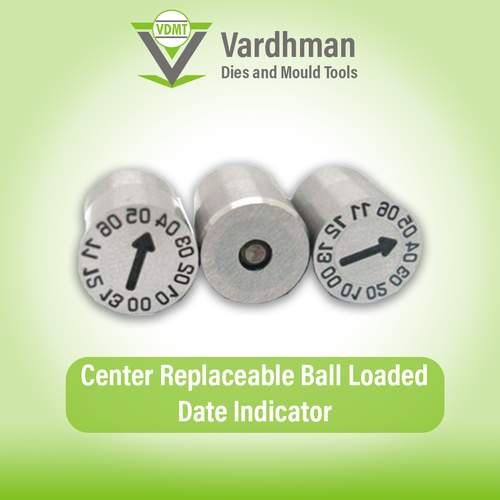

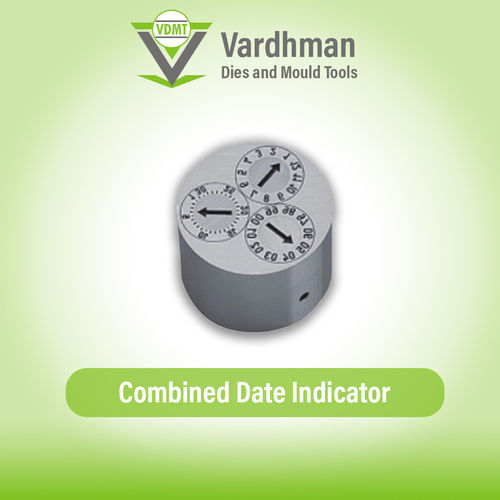

The Center Replaceable Screw Type is a highly efficient and versatile component designed for use in a wide range of tooling, moulding, and die-casting systems. Manufactured by Vardhman Dies & Mould Tools, this component offers easy maintenance and enhanced operational performance, making it a key part of any high-precision moulding system.

Cost Efficiency: By replacing only the screw instead of the entire system, you can save on replacement costs and avoid unnecessary downtime.

- Improved Performance: The center replaceable screw type ensures smooth operation with minimal friction, which improves the overall efficiency of your tooling system.

- Longer Service Life: Due to its high-quality materials and corrosion-resistant design, the component is designed for a longer operational life.

- Reduced Maintenance Efforts: The replaceable screw feature simplifies maintenance and allows for easy, quick servicing, ensuring that your equipment remains in optimal working condition with minimal effort.

- Versatile Use: Suitable for a wide range of applications, from plastic moulding to die-casting, this component enhances the performance of multiple systems across various industries.

Applications of Center Replaceable Screw Type

-

- Injection Moulding: The center replaceable screw type plays a crucial role in maintaining precision and smooth movement in injection moulding machines, helping produce accurate and consistent plastic parts.

- Die-Casting: In die-casting, this component helps maintain the alignment and functioning of the mould, providing a smooth and reliable operation, even under high-pressure conditions.

- Rubber Moulding: In rubber moulding applications, the screw type ensures efficient and precise handling of raw materials, contributing to high-quality finished products.

- Automotive Manufacturing: Used in automotive parts manufacturing, the center replaceable screw type ensures that critical parts maintain accurate specifications throughout production.

- Electronics Manufacturing: For producing small and intricate electronic components, the screw type offers precision and smooth operation, reducing the risk of defects in the final product.

Exceptional Precision and Finishing

Offering a remarkable surface finish of 0.1 to 0.04 microns, the Center Replaceable Screw Type guarantees minimal friction and enhanced performance in mould base applications. The smooth surface supports longevity and reliability under rigorous industrial conditions while facilitating seamless assembly and maintenance.

Superior Material Construction

Engineered with SUS-420 core material and an aluminum body, this screw type is designed to resist wear and corrosion. Its silver color adds aesthetic appeal and indicates the premium quality of materials selected for long-term durability and efficiency in industrial environments.

FAQs of Center Replaceable Screw Type:

Q: How is the Center Replaceable Screw Type installed in industrial mould bases?

A: Installation involves aligning the screw with the designated slot on the mould base, securing it using standard tools, and ensuring the core fits tightly for optimum performance. Skilled technicians can complete the installation, which benefits from the components replaceable center design.Q: What are the advantages of using a SUS-420 core material?

A: SUS-420 is a stainless steel grade prized for its high hardness, corrosion resistance, and mechanical strength. Using this core material boosts the screws lifespan and maintains reliability when used in demanding industrial mould bases.Q: When should industries consider replacing their Center Replaceable Screw Type?

A: Replacement is recommended upon visible wear, decreased performance, or after extensive use within the warranty period. The replaceable design makes maintenance straightforward, contributing to economic and operational efficiency.Q: Where can I purchase the Center Replaceable Screw Type in India?

A: This product is available through reputable exporters, manufacturers, suppliers, and traders in India. You can contact authorized distributors or connect directly with the supplier for additional support and purchase arrangements.Q: What is the process for warranty claims on this product?

A: If you encounter manufacturing defects or performance issues within one year of purchase, contact your supplier with purchase documentation. Qualified warranties generally cover repairs or replacements subject to suppliers terms and conditions.Q: How is this product typically used in industrial settings?

A: It is primarily utilized within mould base components, supporting manufacturing operations in diverse industries. Its design ensures stable, precise alignment under heavy-duty use, contributing to consistent output and efficient cycle times.Q: What benefits does the 0.1-0.04 micron surface finish provide?

A: A fine surface finish minimizes friction and wear during operation, enhancing efficiency, dimensional accuracy, and service life of the screw in mould base systems. It supports smoother cycles and lower maintenance requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free