எங்களை அழைக்கவும்

08045479560

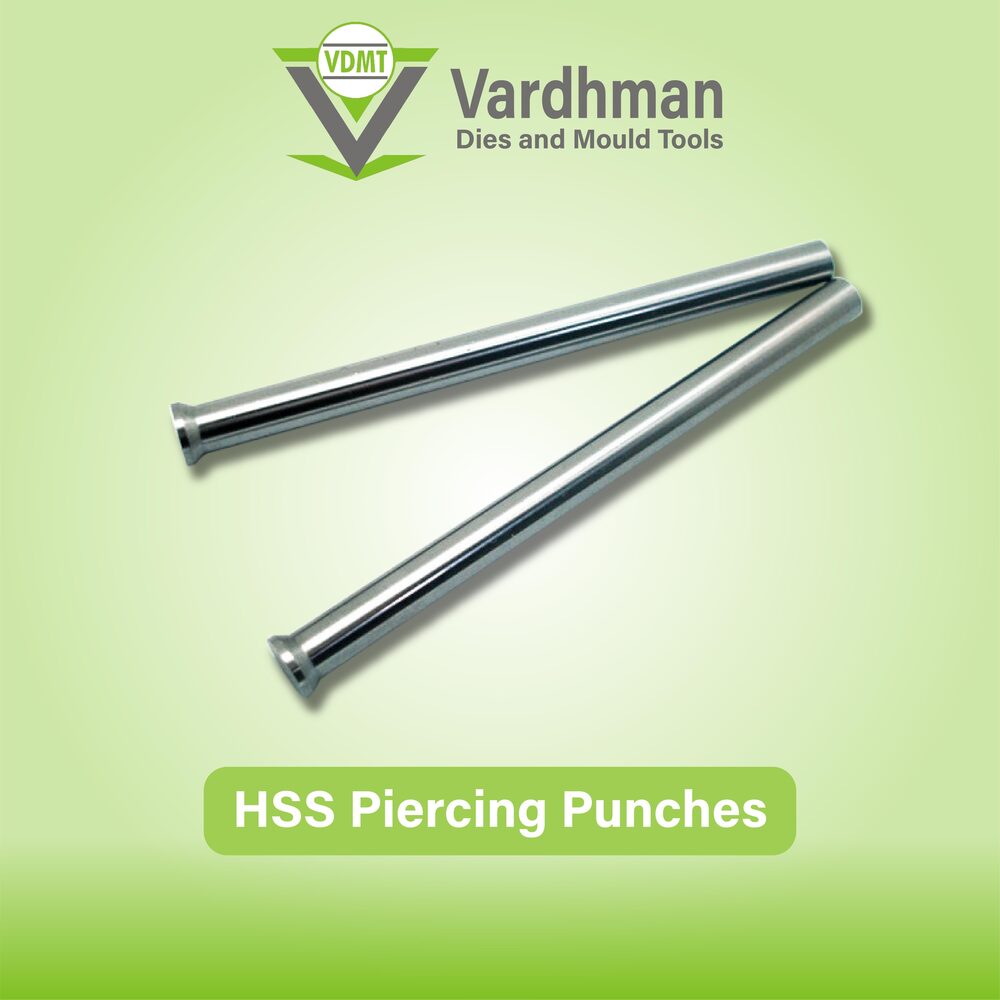

Piercing Punches

40 INR/Unit

தயாரிப்பு விவரங்கள்:

- கோர் பொருள் Steel

- பயன்பாடு Engineering industry

- பொருள்

- அளவு Customized

- தயாரிப்பு வகை Piercing Punches

- கலர் Silvar

- உத்தரவாதத்தை 1 Year

- மேலும் பார்க்க கிளிக் செய்யவும்

X

விலை மற்றும் அளவு

- 20

தயாரிப்பு விவரக்குறிப்புகள்

- Silvar

- 1 Year

- Steel

- Customized

- Engineering industry

- Piercing Punches

வர்த்தகத் தகவல்கள்

- , ,

- வாரத்திற்கு

- வாரம்

- Carton packaging / As per client's requirement.

- We provide Test & hardness சான்றிதழ் also NSIC and ISO Certified.

தயாரிப்பு விளக்கம்

Piercing Punches “ by Vardhman Dies & Mould Tools

Key Features:

- High-Quality Material: Manufactured using premium-grade tool steel, ensuring durability and superior wear resistance.

- Precision Engineering: Designed with high dimensional accuracy for efficient and consistent punching operations.

- Heat Treatment Process: Hardened for optimal strength, ensuring longevity and performance in high-pressure applications.

- Corrosion & Abrasion Resistant: Special coating options available to enhance resistance to rust, heat, and wear.

- Customizable Designs: Available in various sizes and shapes to meet specific industry needs.

- High Productivity: Provides smooth and precise cuts, reducing material wastage and improving efficiency.

-

Applications:

- Sheet Metal Processing: Ideal for punching holes in metal sheets, ensuring clean and precise cuts.

- Press Tools & Dies: Essential for stamping, blanking, and forming operations in manufacturing industries.

- Automotive & Aerospace Industry: Used for precision cutting and shaping in high-performance applications.

- Electronics & Electrical Components: Assists in fine-detail punching for electrical enclosures and components.

- General Metalworking: Suitable for various industrial applications requiring accurate piercing and hole-cutting.

Vardhman Dies & Mould Tools is a leading manufacturer, exporter, and supplier of high-quality Piercing Punches in India, known for delivering reliable and efficient tooling solutions.

Precision Construction and Reliability

Expertly crafted from premium steel, these Piercing Punches guarantee robust operational life and dimensional accuracy. Our dedication to manufacturing excellence ensures that each punch maintains high resistance to deformation, making them ideal for repetitive engineering processes.

Custom Solutions for Diverse Needs

We understand that every engineering project is unique. Thats why our Piercing Punches are available in customizable sizes, allowing clients to specify requirements for their exact application. Our team works closely with customers to deliver punches that excel in both performance and longevity.

FAQs of Piercing Punches:

Q: How are Piercing Punches used in the engineering industry?

A: Piercing Punches are employed to create precise holes or shapes in a variety of materials during manufacturing processes. They are commonly integrated into press machines and are essential for tasks such as metal forming, component assembly, and fabrication.Q: What makes your Piercing Punches stand out from others in the market?

A: Our Piercing Punches are produced from high-quality steel with a silvar finish for enhanced durability and corrosion resistance. Their customizable sizes and one-year warranty ensure they meet the specific requirements of engineering projects while providing long-term value.Q: When should I consider replacing Piercing Punches?

A: Punches should be replaced when signs of excessive wear, chipping, or dimensional loss are noticed, typically after extended use. Regular inspections can help ensure continued accuracy and safety in operations.Q: Where are your Piercing Punches manufactured and supplied?

A: We manufacture our Piercing Punches in India and supply them as an exporter, manufacturer, supplier, and trader across domestic and international markets. Our widespread distribution network ensures timely delivery to clients worldwide.Q: What is the process for customizing the size of Piercing Punches?

A: Customers can specify the desired dimensions for their application, after which our engineering team develops the punch accordingly. Throughout production, stringent quality controls are maintained to ensure precision and compatibility with customer needs.Q: How can I benefit from using these steel, silvar-finish Piercing Punches?

A: Using our robust steel Piercing Punches enhances process efficiency, reduces tool change frequency, and maintains high-quality output, contributing to overall productivity and reliability in industrial operations.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

என்னை இலவசமாக அழைக்கவும்

என்னை இலவசமாக அழைக்கவும்