Call Us

08045479560

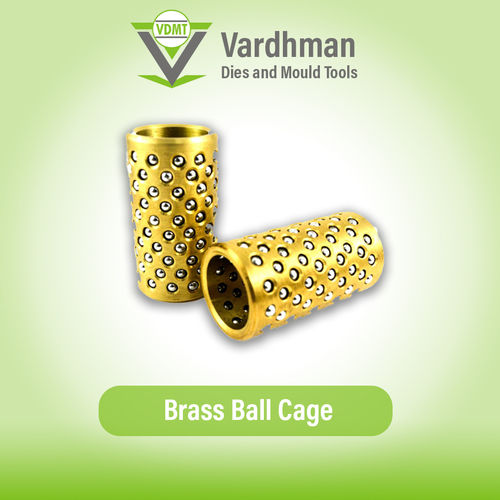

Plastic Ball Cage

Product Details:

- Core Material Plastic

- Usage Industries

- Material Plastic

- Size Surface Finish: 0.3 micron -.04 micron

- Shaping Mode Plastic Mould

- Punch Dies Round

- Product Type Plastic Ball Cage

- Click to View more

Plastic Ball Cage Price And Quantity

- 50 INR/Piece

- 25 Piece

- 10.00 - 100.00 INR/Piece

Plastic Ball Cage Product Specifications

- Round

- Plastic

- Surface Finish: 0.3 micron -.04 micron

- Plastic Mould

- Plastic

- 50 mm / 70 mm / 80 mm / 100 mm Millimeter (mm)

- Plastic

- Plastic Ball Cage

- Industries

Plastic Ball Cage Trade Information

- 100000 Piece Per Month

- 7 Days

- Carton packaging / As per client's requirement.Plastic Ball Cage

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

Looking for a High-Quality Plastic Material- Made from durable, wear-resistant plastic for lightweight yet robust performance.

Smooth Operation Ensures low friction and uniform spacing between bearing balls.

Corrosion-Resistant- Ideal for moisture-prone and high-humidity environments.

Lightweight & Cost-Effective-Reduces overall system weight, improving energy efficiency.

Wide Compatibility- Available in different sizes and configurations to fit various industrial applications.

Minimal Maintenance-Does not require lubrication, ensuring hassle-free performance.

Applications of Plastic Ball Cage

Mould & Die Industries

Press Tool Accessories

Precision Bearings & Machinery

Automotive Components

Medical Equipment

Aerospace & Industrial Applications

Precision Engineered for Industrial Applications

Our Plastic Ball Cages are designed using precise plastic mould shaping methods and feature a fine surface finish for compatibility with various industrial systems. They are available in multiple lengths to suit a wide array of applications, ensuring operational efficiency and durability.

Complete Range of Length Variations

Choose from 50 mm, 70 mm, 80 mm, and 100 mm lengths to meet specific requirements in different machinery and equipment. The flexibility in sizing allows seamless integration into both standard and custom setups.

FAQs of Plastic Ball Cage:

Q: How is the Plastic Ball Cage manufactured?

A: The Plastic Ball Cage is produced using advanced plastic mould shaping processes, ensuring precise dimensions and robust construction for reliable industrial use.Q: What industries commonly use Plastic Ball Cages?

A: These ball cages are widely used across various industriesincluding automotive, automation, manufacturing, and machinerywhere reliable and smooth linear or rotary motion is essential.Q: When should I choose a Plastic Ball Cage over metal alternatives?

A: Plastic Ball Cages are ideal when low friction, corrosion resistance, and quiet operation are required. They are also preferable in environments where lubrication must be minimized or where metal-to-metal contact is undesirable.Q: Where are your Plastic Ball Cages exported from?

A: We export and supply our Plastic Ball Cages from India, serving clients worldwide with a reputation for quality and timely delivery.Q: What is the process involved in achieving a 0.3 micron to 0.04 micron surface finish?

A: Our manufacturing process incorporates advanced polishing and moulding techniques to achieve the specified fine surface finish, ensuring minimal friction and extended lifetime in operational use.Q: How are different size options for the Plastic Ball Cage determined?

A: Size options such as 50 mm, 70 mm, 80 mm, and 100 mm are determined based on standard industry requirements, but we also offer customization depending on the specific needs of your application.Q: What are the key benefits of choosing your Plastic Ball Cage?

A: Selecting our Plastic Ball Cage offers advantages such as high precision, corrosion resistance, lightweight design, ease of installation, and suitability for a broad spectrum of industrial tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free