Call Us

08045479560

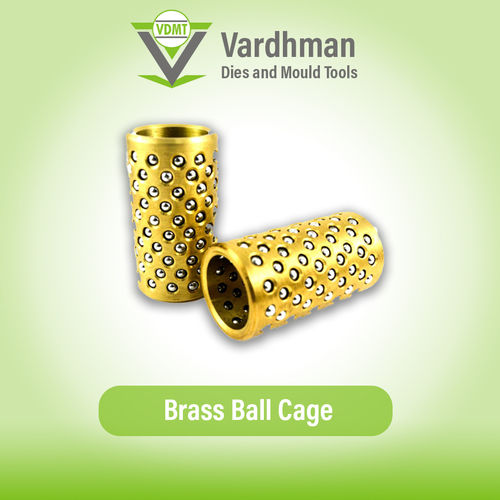

Brass Ball Cage

Product Details:

- Mould Base Round

- Core Material brass

- Usage Industries

- Material Other

- Size Surface Finish: 0.3 micron -.04 micron

- Product Type Brass Ball Cage

- Die Head round

- Click to View more

Brass Ball Cage Price And Quantity

- 50 INR/Piece

- 25 Piece

Brass Ball Cage Product Specifications

- 50 mm / 70 mm / 80 mm / 100 mm Millimeter (mm)

- Brass Ball Cage

- Brass

- Round

- round

- Surface Finish: 0.3 micron -.04 micron

- Industries

- brass

- Other

Brass Ball Cage Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Piece Per Month

- 7 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

Brass Ball Cages are precision components designed for guiding and holding ball bearings in linear motion and rotational systems. Known for their excellent strength, corrosion resistance, and thermal conductivity, these cages are ideal for a variety of industrial applications where durability and precision are paramount. Brass ball cages are preferred in environments requiring low maintenance and high reliability, offering seamless operation in high-performance systems.

Key Features of Brass Ball Cages

-

Superior Durability

- Made from high-quality brass, ensuring long service life even under demanding conditions.

-

Corrosion Resistance

- Highly resistant to rust and chemical exposure, suitable for harsh environments.

-

Excellent Thermal Conductivity

-

- Efficient in heat dissipation, preventing system overheating.

-

Noise Reduction

- Brass offers natural damping properties, minimizing operational noise.

-

Customizable Configurations

- Available in various sizes, designs, and ball configurations to suit specific applications.

-

Applications of Brass Ball Cages

-

Tooling and Machinery

- Widely used in guiding systems of precision tooling and heavy machinery.

-

Automotive Components

- Integral to steering systems, gearboxes, and suspension systems.

-

Aerospace Applications

- Preferred for lightweight and durable guiding solutions in aircraft systems.

-

Medical Equipment

- Commonly used in high-precision medical devices for smooth operation.

-

Robotics and Automation

- Ensures precision movement in robotic arms and automated systems.

-

Electrical Applications

- Reliable in electrical components due to excellent conductivity and heat resistance.

Advantages of Brass Ball Cages

-

High Load Capacity

- Can withstand significant loads without deformation or failure.

-

Corrosion and Wear Resistance

- Provides extended life in both dry and lubricated environments.

-

Ease of Maintenance

- Brasss natural anti-corrosion properties reduce the need for frequent maintenance.

-

Enhanced System Performance

- Offers smooth motion with minimal friction and noise.

-

Versatility

- Suitable for both low and high-speed applications.

Versatile Design and Build

The Brass Ball Cage features a robust round mould base and die head, suitable for a wide range of industrial systems. Its precision engineering guarantees compatibility and effective load management, making it a choice component in demanding settings.

Superior Surface Finish

A key highlight of this product is its exceptional surface finish, ranging from 0.3 micron to 0.04 micron. Such fine detailing minimizes friction, enhances movement smoothness, and contributes to extended equipment longevity in varied industrial operations.

Available Lengths and Applications

Offered in various lengths, including 50 mm, 70 mm, 80 mm, and 100 mm, the Brass Ball Cage fits diverse machinery specifications. Its reliability ensures seamless usage in manufacturing, automotive, and other industrial segments, fostering efficient operation.

FAQs of Brass Ball Cage:

Q: How is the Brass Ball Cage typically installed in industrial equipment?

A: The Brass Ball Cage is designed for easy installation into round die heads and mould bases. Fitment usually involves inserting the cage within a pre-machined slot or cavity in the equipment, securing it to allow smooth ball movement and proper alignment.Q: What are the primary uses of a Brass Ball Cage in industries?

A: Brass Ball Cages are commonly utilized to support and guide moving components in machines, reducing friction and wear. They are essential in applications such as jigs, fixtures, and automated systems, where precision and durability are critical.Q: When should I consider replacing a Brass Ball Cage?

A: Replacement is recommended when you observe increased friction, signs of wear, or irregular motion within your machinery. Regular maintenance checks can help identify when the ball cage should be changed to uphold efficient performance.Q: Where is the Brass Ball Cage manufactured and exported from?

A: Our Brass Ball Cages are manufactured in India, where we also serve as exporters, suppliers, and traders to a broad international market, ensuring reliable global delivery.Q: What processes are involved in achieving the 0.30.04 micron surface finish?

A: The surface finish of 0.30.04 micron is accomplished through precision machining and fine polishing. These processes refine the brass surface, guaranteeing minimal roughness and optimal interaction with moving components.Q: How does using a brass core material benefit industrial applications?

A: Brass provides excellent corrosion resistance, high strength, and low friction characteristics. These properties extend the operational life of the ball cage while ensuring consistent performance under demanding industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free