Call Us

08045479560

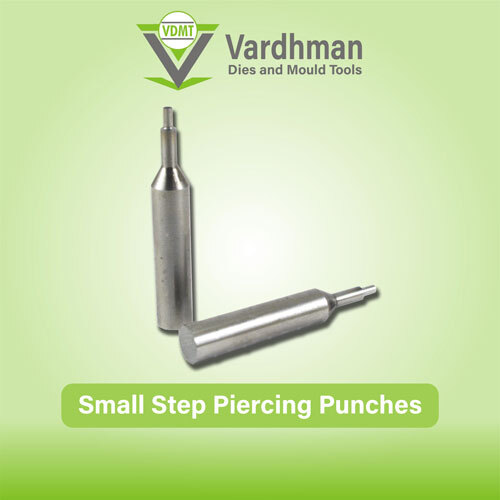

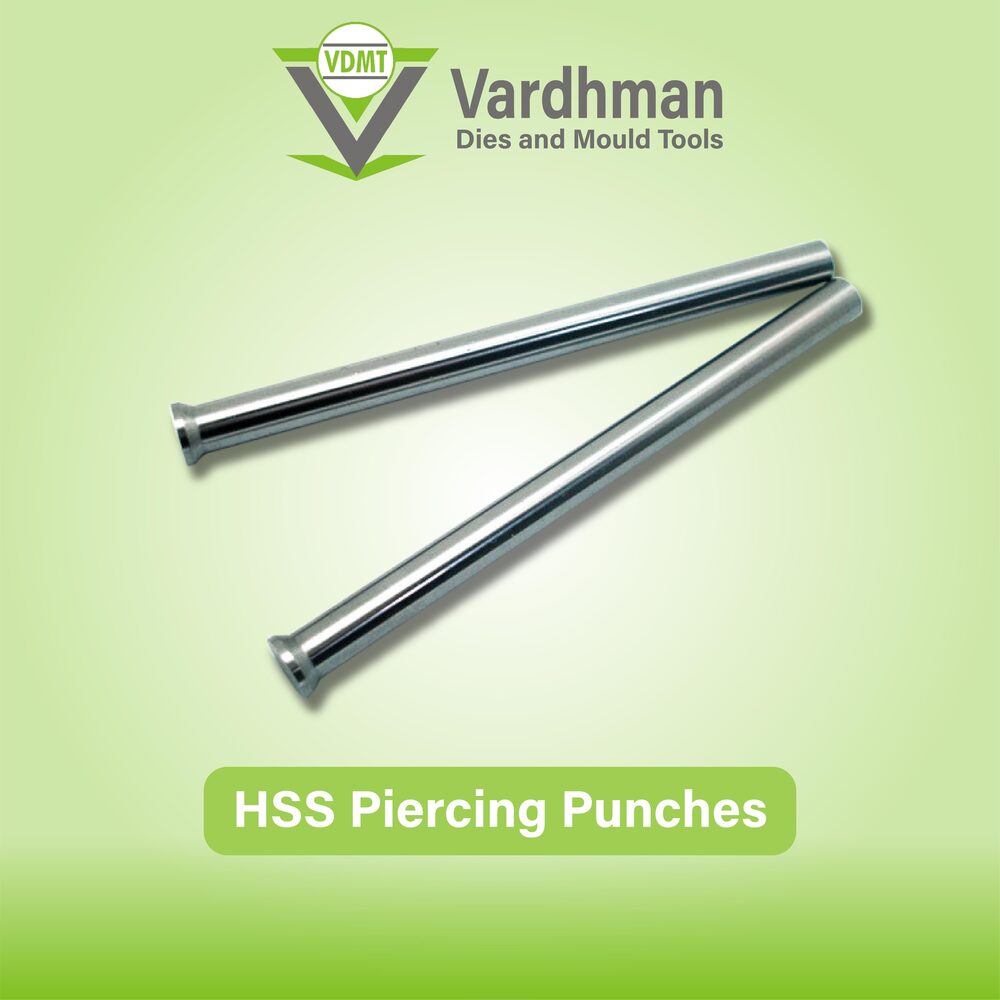

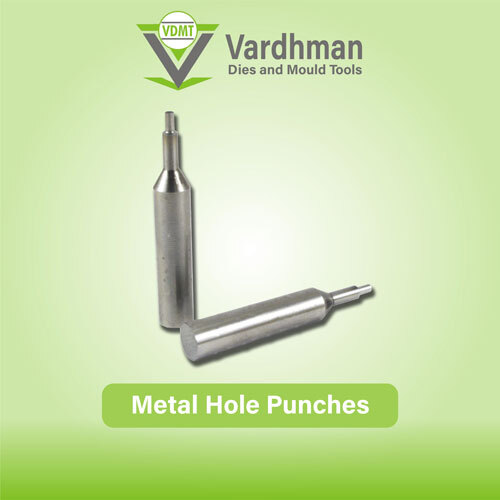

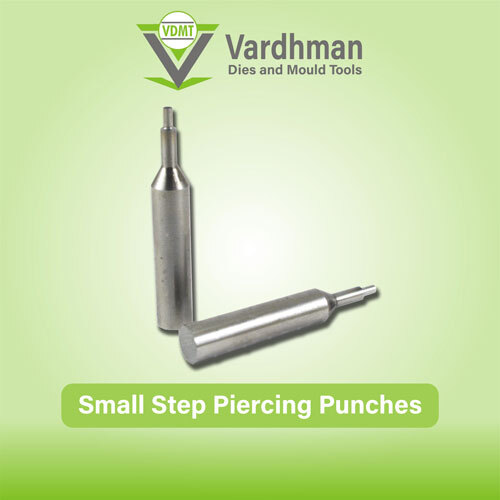

Carbide Punches

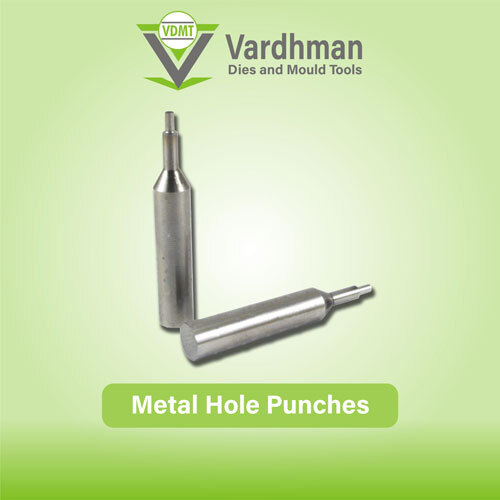

Product Details:

- Usage Industrial

- Material Metal

- Size Dimension 0.2 mm 50 mm dia

- Product Type Carbide Punches

- Color Silver

- Width Surface Finish: 0.3 micron - 0.04 micron Micromete (micron)

- Length 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Click to View more

Carbide Punches Price And Quantity

- 50 INR/Piece

- 25 Piece

- 10.00 - 100.00 INR/Piece

Carbide Punches Product Specifications

- Silver

- Metal

- Surface Finish: 0.3 micron - 0.04 micron Micromete (micron)

- Carbide Punches

- Dimension 0.2 mm 50 mm dia

- 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Industrial

Carbide Punches Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Piece Per Month

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

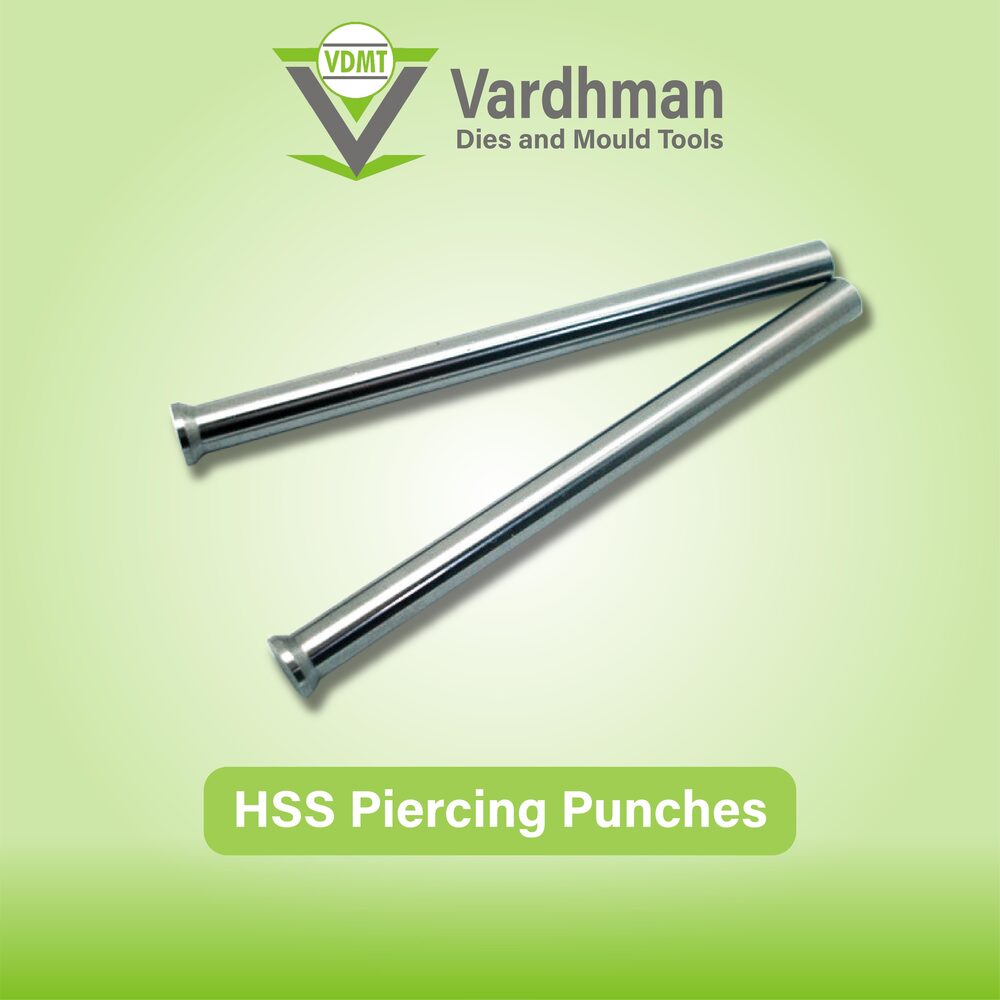

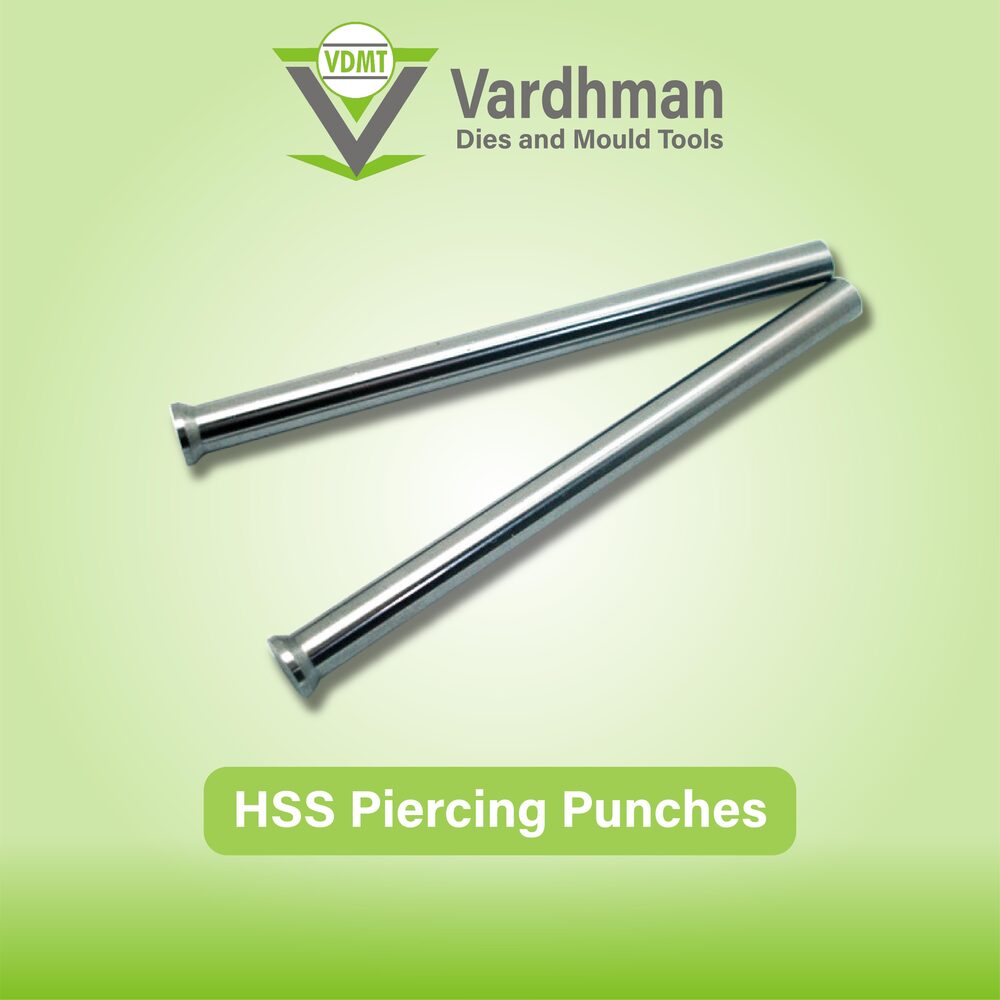

Carbide Punches are premium punching tools made from high-quality tungsten carbide, renowned for their exceptional hardness, durability, and wear resistance. These punches are ideal for applications requiring precision, toughness, and resistance to extreme wear and heat.

Carbide punches are extensively used in industries like metalworking, automotive, aerospace, and tool and die manufacturing, where long-lasting tools are essential for punching or shaping materials such as metal sheets, alloys, plastics, and more.

Key Features of Carbide Punches

-

Superior Hardness

- Crafted from tungsten carbide, offering unmatched resistance to wear and deformation, even under high-stress conditions.

-

Heat Resistance

- Retains performance and structural integrity at elevated temperatures, making it ideal for heavy-duty and high-speed applications.

-

Corrosion Resistance

-

- Highly resistant to corrosion, ensuring prolonged usability in demanding environments.

-

Customizable Designs

- Available in various sizes, shapes, and specifications to meet diverse industrial needs.

Applications of Carbide Punches

-

Metal Stamping

- Used for high-precision stamping and shaping operations in sheet metal fabrication.

-

Automotive Industry

- Essential for punching and shaping components like gaskets, engine parts, and panels.

-

Aerospace Manufacturing

- Delivers precision in punching lightweight and durable components for aircraft.

-

Tool & Die Making

- Utilized in die-making operations requiring accuracy and longevity.

-

General Manufacturing

- Suitable for punching and perforating a wide range of materials in diverse manufacturing setups.

Advantages of Carbide Punches

-

Extended Tool Life

- Outlasts conventional punches due to its superior hardness and wear resistance.

-

High Efficiency

- Maintains precision and performance over extended use, minimizing downtime.

-

Cost-Effective

- Reduces replacement and maintenance costs due to its durability.

-

Versatility

- Suitable for a wide range of materials and industrial applications.

-

Improved Productivity

- Reliable performance leads to consistent results, boosting overall operational efficiency.

High-Precision Carbide Punches

Engineered to meet the demands of industrial applications, our carbide punches deliver precision and consistency. Each punch is crafted with meticulous attention to detail, ensuring a uniform finish and exact measurements. With a wide range of dimensions and customizable options, these punches support a variety of manufacturing and production needs.

Exceptional Surface Finish for Superior Performance

Our punches achieve a surface finish between 0.3 micron and 0.04 micron, minimizing tool wear and optimizing performance. This high-quality finish ensures smooth operation and reduces friction, which is essential for achieving accurate results in high-volume industrial environments.

FAQs of Carbide Punches:

Q: How are carbide punches utilized in industrial applications?

A: Carbide punches are primarily used for accurate hole-punching, forming, and metal stamping in various industries. Their precision and durability make them suitable for high-volume production tasks, including automotive, electronics, and machinery manufacturing.Q: What distinguishes your carbide punches in terms of material and finish?

A: Our punches are made from high-quality metal carbide and feature a surface finish ranging from 0.3 to 0.04 microns, ensuring increased durability, reduced friction, and extended lifespan compared to standard punches.Q: When should I consider custom length or dimensions for these punches?

A: Custom lengths or dimensions are recommended when standard sizes do not fit your specific application or machine setup, allowing for optimal performance and compatibility with your industrial processes.Q: Where are your carbide punches manufactured and supplied from?

A: We manufacture and supply our carbide punches from India, catering to both domestic and international markets as a trusted exporter, manufacturer, supplier, and trader.Q: What is the process behind manufacturing your carbide punches?

A: The production process begins with selecting premium-metal carbide, followed by precision machining to achieve tight tolerances and superior surface finish. Each punch is then inspected for quality assurance before shipment.Q: What are the key benefits of using your carbide punches?

A: Our carbide punches offer remarkable wear resistance, prolonged tool life, and consistently accurate results. Their superior finish reduces maintenance needs and downtime, maximizing productivity in industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free