Call Us

08045479560

Double Step Ejector Pins

60 INR/Unit

Product Details:

- Mould Base Mould base

- Usage Engineering industry

- Material Steel

- Shaping Mode Punching Mould

- Size Surface Finish: 0.3-micron -.04 micron

- Product Type Double Step Ejector Pins

- Color Silver

- Click to View more

X

Double Step Ejector Pins Price And Quantity

- 50 Unit

- 60 INR/Unit

Double Step Ejector Pins Product Specifications

- Steel

- Mould base

- Punching Mould

- Double Step Ejector Pins

- 1 year

- Engineering industry

- 100 - 600 mm Millimeter (mm)

- Surface Finish: 0.3-micron -.04 micron

- Silver

Double Step Ejector Pins Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Week

- 7 Days

- Carton packaging /As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

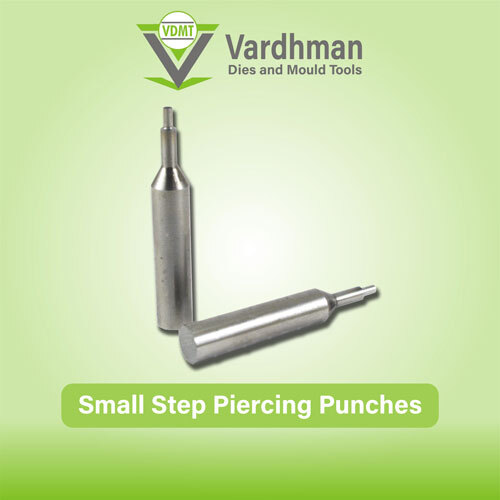

Double Step Ejector Pins are specialized components used in injection molding processes to ensure efficient and controlled ejection of molded parts. These pins feature a double-step design, providing additional functionality and precision during the ejection process.

Advantages of Using Double Step Ejector Pins

- Controlled Ejection Process:

-

- Minimizes damage to molded parts and enhances product quality.

-

Reduced Wear and Tear:

- The double-step design reduces stress on the mold and pins, prolonging their service life.

-

Versatile Applications:

- Suitable for use in intricate molds and high-precision molding operations.

-

Improved Efficiency:

- Smooth and reliable ejection reduces cycle times and maintenance needs.

-

Automotive Industry:

- Ejecting complex and high-precision automotive components.

-

Medical Devices:

- Ensuring clean and precise ejection for delicate medical components.

-

Electronics Manufacturing:

- Suitable for small and intricate parts required in the electronics sector.

-

Packaging:

- Used in the production of lightweight and delicate packaging materials.

-

Aerospace Components:

- Ideal for high-performance parts with strict dimensional tolerances.

Superior Quality for Demanding Applications

Our Double Step Ejector Pins deliver precision and strength, manufactured from premium steel and finished to a high tolerance. With a sleek silver appearance, they suit a wide range of engineering uses, particularly in mould bases and punching applications, guaranteeing consistent performance even under challenging conditions.

Enhanced Durability and Performance

Featuring a surface finish between 0.3 and 0.04 microns, these ejector pins minimize friction and wear, extending the life of both the pin and the mould. Their robust design ensures that they withstand repeated use in high-stress environments typical of the engineering sector.

FAQs of Double Step Ejector Pins:

Q: How are Double Step Ejector Pins used in the engineering industry?

A: Double Step Ejector Pins are primarily used to eject molded components from mould bases in the engineering industry. Their double step design ensures smooth ejection and helps protect the mould from potential damage during the production process.Q: What materials are used to manufacture these ejector pins?

A: Our Double Step Ejector Pins are manufactured from high-quality steel, offering strength and resistance to wear, making them particularly suitable for demanding engineering applications.Q: When should I replace Double Step Ejector Pins in my mould base?

A: You should consider replacing the ejector pins if you observe signs of wear, reduced precision, or if the pins no longer provide smooth ejection. Regular inspection, especially within the warranty period of 1 year, helps prevent downtime and ensures product quality.Q: Where are your Double Step Ejector Pins manufactured and supplied from?

A: We are an exporter, manufacturer, supplier, and trader based in India, delivering Double Step Ejector Pins to various regions worldwide, catering to the needs of the global engineering and mould-making sectors.Q: What is the process for installing Double Step Ejector Pins in a mould base?

A: The pin is inserted into the designated hole of the mould base, ensuring it aligns properly with the ejection path. Proper installation helps ensure smooth operation and maximizes the lifespan of both the pin and the mould.Q: What are the benefits of using these Double Step Ejector Pins?

A: Benefits include a high-quality surface finish for minimal friction, enhanced durability, precise component ejection, and a 1-year warranty, making them a reliable choice for continuous engineering applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free