Call Us

08045479560

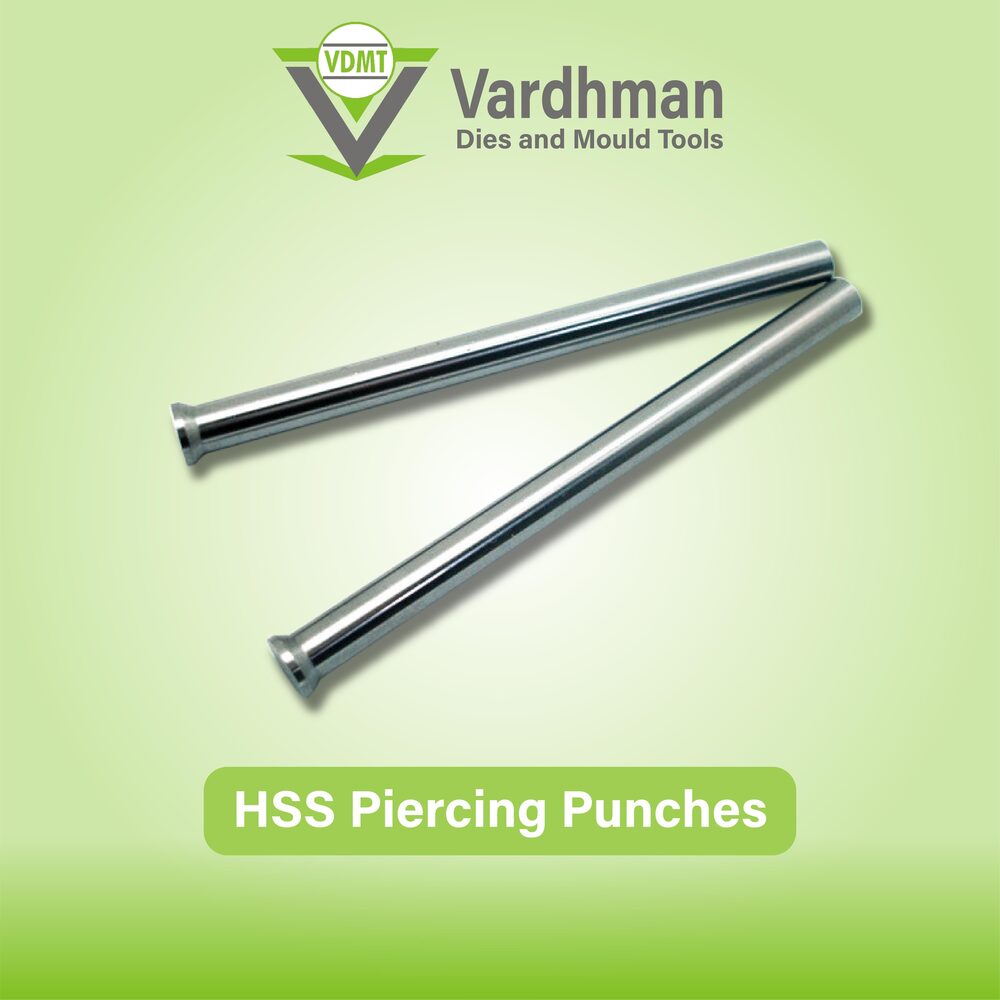

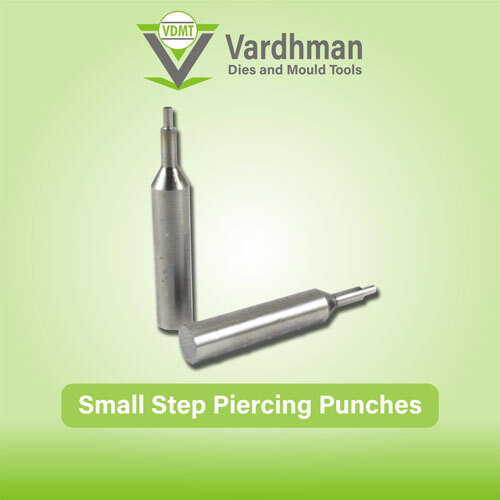

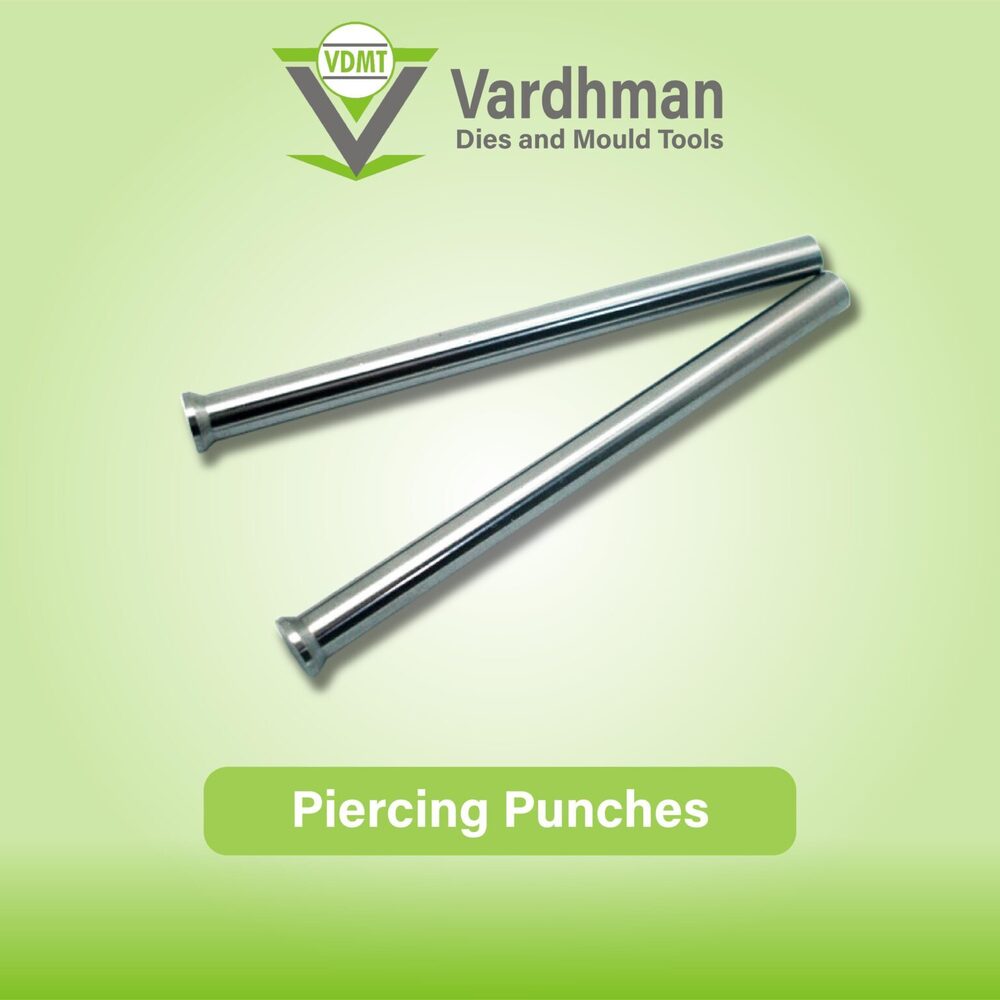

HSS Step Punches A Type

40 INR/Unit

Product Details:

- Core Material HSS M2 - M42- M35

- Mould Base Mould base

- Usage Industries

- Material Metal

- Size 0.3 micron 0.04 micron

- Height Surface Finish: 0.3 micron - 0.04 micron Micromete (micron)

- Product Type HSS Step Punches

- Click to View more

X

HSS Step Punches A Type Price And Quantity

- 40 INR/Unit

- 20 Unit

HSS Step Punches A Type Product Specifications

- HSS Step Punches

- 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Industries

- Metal

- HSS M2 - M42- M35

- Silver

- 1 year

- Mould base

- Surface Finish: 0.3 micron - 0.04 micron Micromete (micron)

- 0.3 micron 0.04 micron

HSS Step Punches A Type Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Week

- 7 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

HSS Step Punches A Type Precision Engineering for Industrial Applications

Key Features:

- High-Speed Steel (HSS) Construction: Manufactured from premium HSS for exceptional strength and durability.

- Superior Hardness & Wear Resistance: Designed to withstand high-impact operations with excellent edge retention.

- Precision Step Design: Ensures accurate punching and piercing with minimal deformation.

- Heat & Corrosion Resistant: Treated for high-temperature resistance, making it ideal for heavy-duty applications.

- Smooth Surface Finish: Enhances longevity and reduces friction during operation.

- Customizable Sizes & Specifications: Available in different sizes to meet specific industrial needs.

Applications:

- Metal Stamping & Press Tools: Ensures accurate and efficient punching operations in sheet metal processing.

- Automotive & Aerospace Industries: Used in the production of precision components for vehicles and aircraft.

- Plastic Injection Moulding: Provides reliable performance in mould-making and shaping processes.

- Die Cutting & Fabrication: Essential for cutting dies in manufacturing and production lines.

- General Engineering & Tooling: Suitable for various industrial punching and forming applications.

-

Vardhman Dies & Mould Tools is a trusted manufacturer and supplier of HSS Step Punches A Type,

Exceptional Surface Finish and Versatility

Crafted with precision, HSS Step Punches A Type achieve a surface finish as fine as 0.04 micron, ensuring clean and accurate punching results. The versatility in length options and customization ensures compatibility with a variety of mould bases and industrial applications. This adaptability makes them the preferred choice for manufacturers seeking both quality and flexibility.

Premium Materials for Long-Lasting Performance

Engineered using high-speed steels like M2, M42, and M35, these step punches display excellent durability and wear resistance. This core material selection enhances performance, even under demanding industrial conditions, ensuring longevity and consistent operation, which translates to cost savings and reduced downtime.

FAQs of HSS Step Punches A Type:

Q: How are HSS Step Punches A Type used in industrial applications?

A: HSS Step Punches A Type are inserted into compatible mould bases to punch precise holes or shapes in various materials, ensuring high accuracy and smooth finishes. They are widely used in manufacturing processes that demand consistent results.Q: What makes the surface finish of 0.3 micron 0.04 micron significant?

A: A surface finish within the range of 0.3 micron to 0.04 micron ensures that punched components have minimal roughness, reducing the need for secondary processing and improving overall product quality.Q: When should I consider customizing the length of my step punch?

A: Customizing the punch length is ideal when standard sizes (50 mm, 70 mm, 80 mm, or 100 mm) do not suit your specific mould base or application requirements. This allows for seamless integration into unique or specialized setups.Q: Where are these HSS Step Punches A Type primarily manufactured and supplied from?

A: These punches are produced and supplied by leading manufacturers and exporters based in India, serving both domestic and international industrial clients.Q: What process is involved in producing these step punches?

A: The production process involves selecting high-speed steel, precision machining to achieve the desired micron surface finish, heat treatment for strength, and quality control checks to ensure exact specifications are met.Q: What benefits does using HSS M2, M42, and M35 offer for step punches?

A: Using HSS grades like M2, M42, and M35 provides excellent hardness, wear resistance, and durability, which is crucial for demanding industrial environments and extends tool life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free