Call Us

08045479560

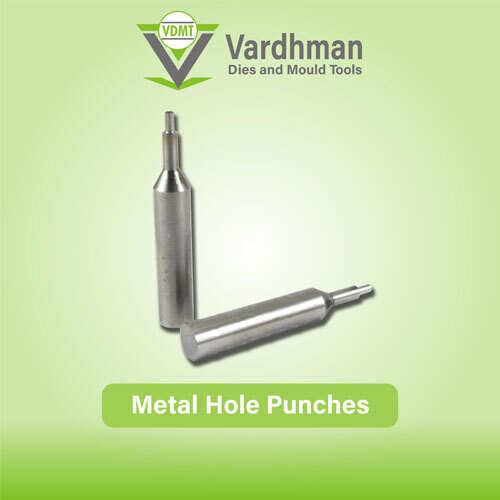

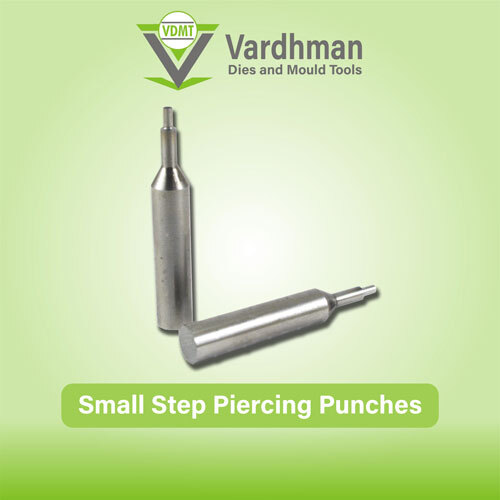

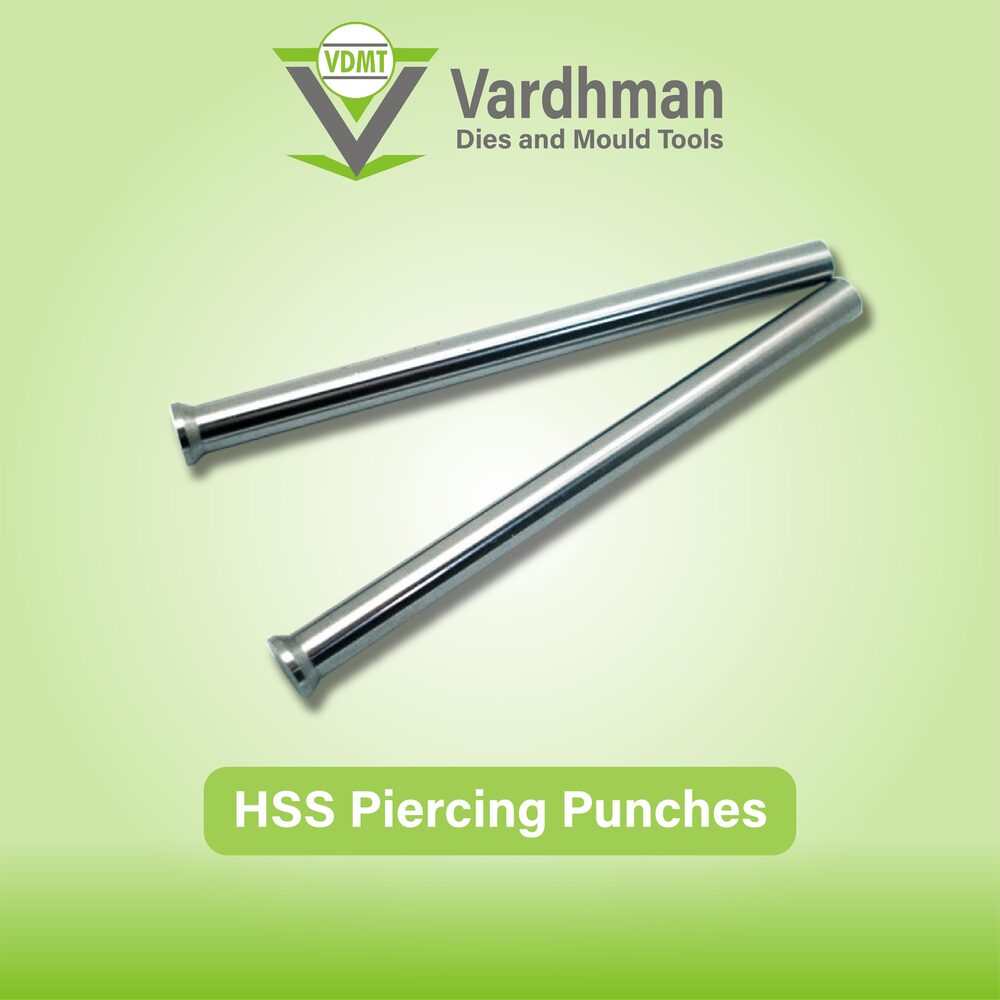

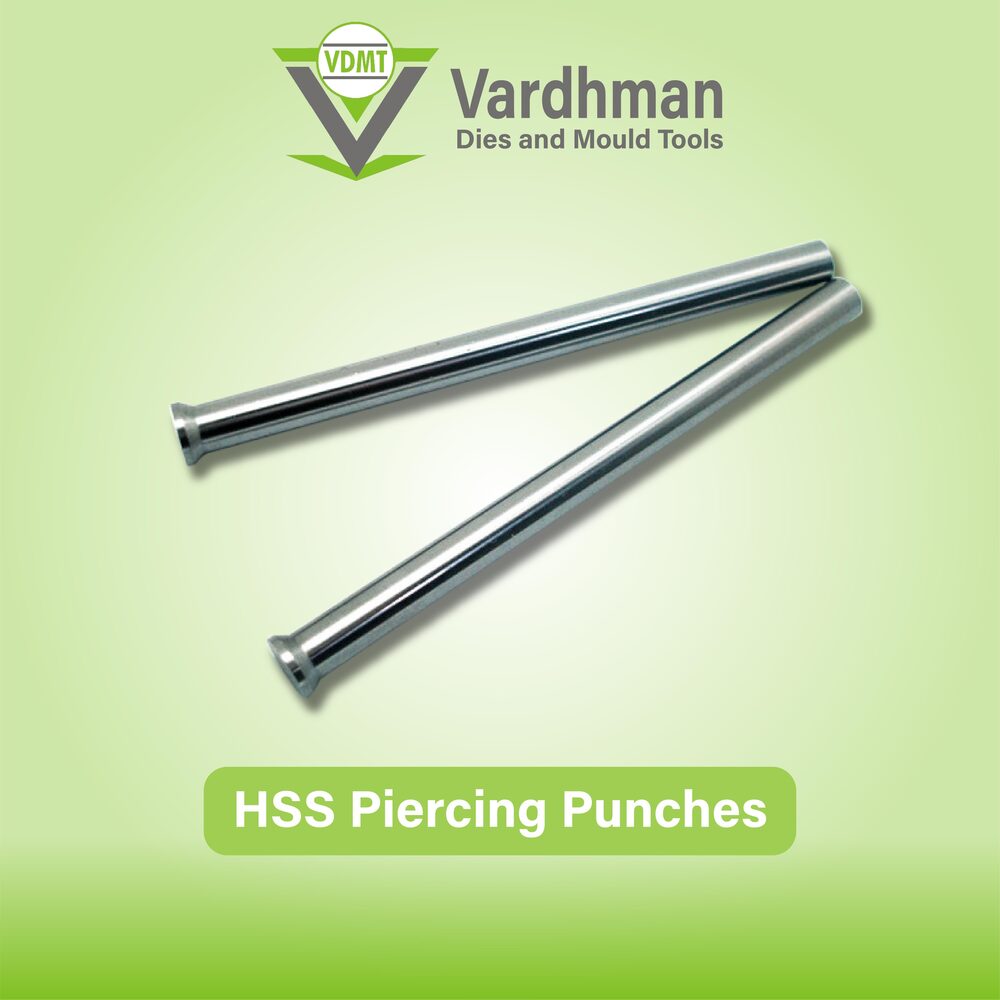

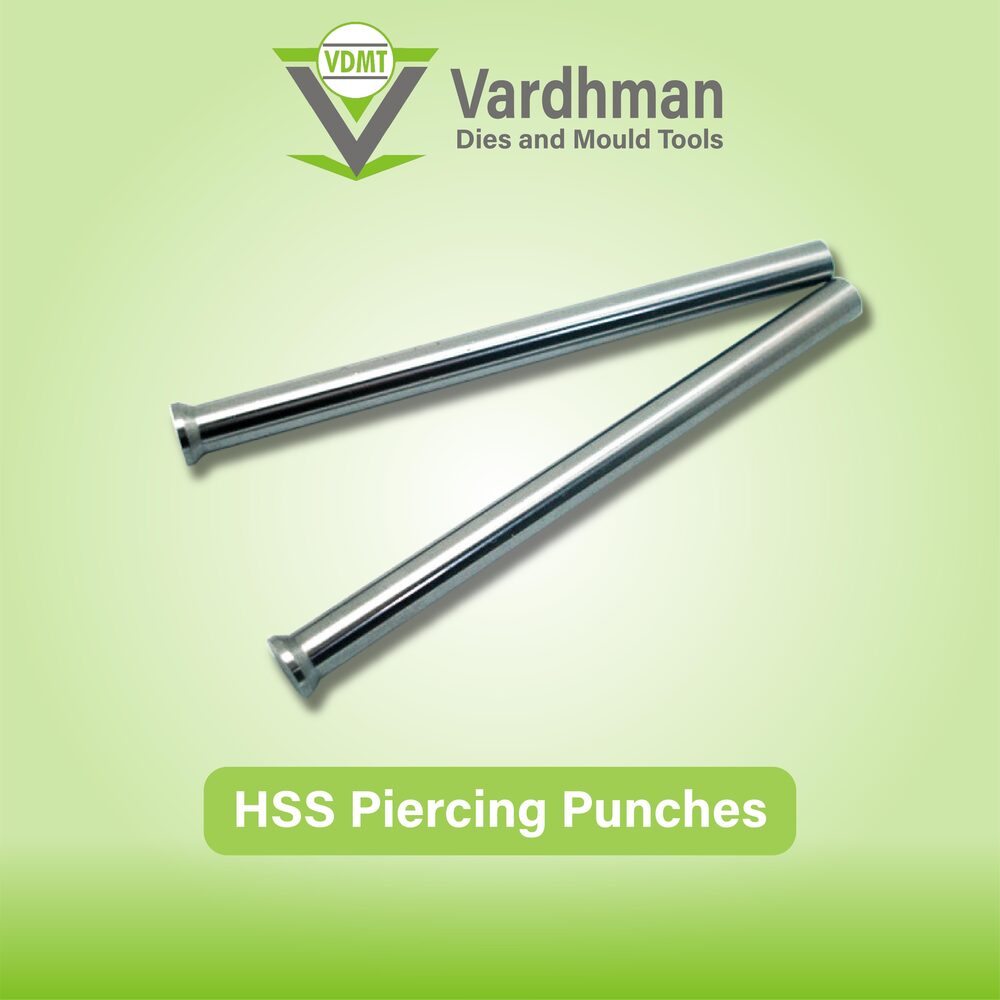

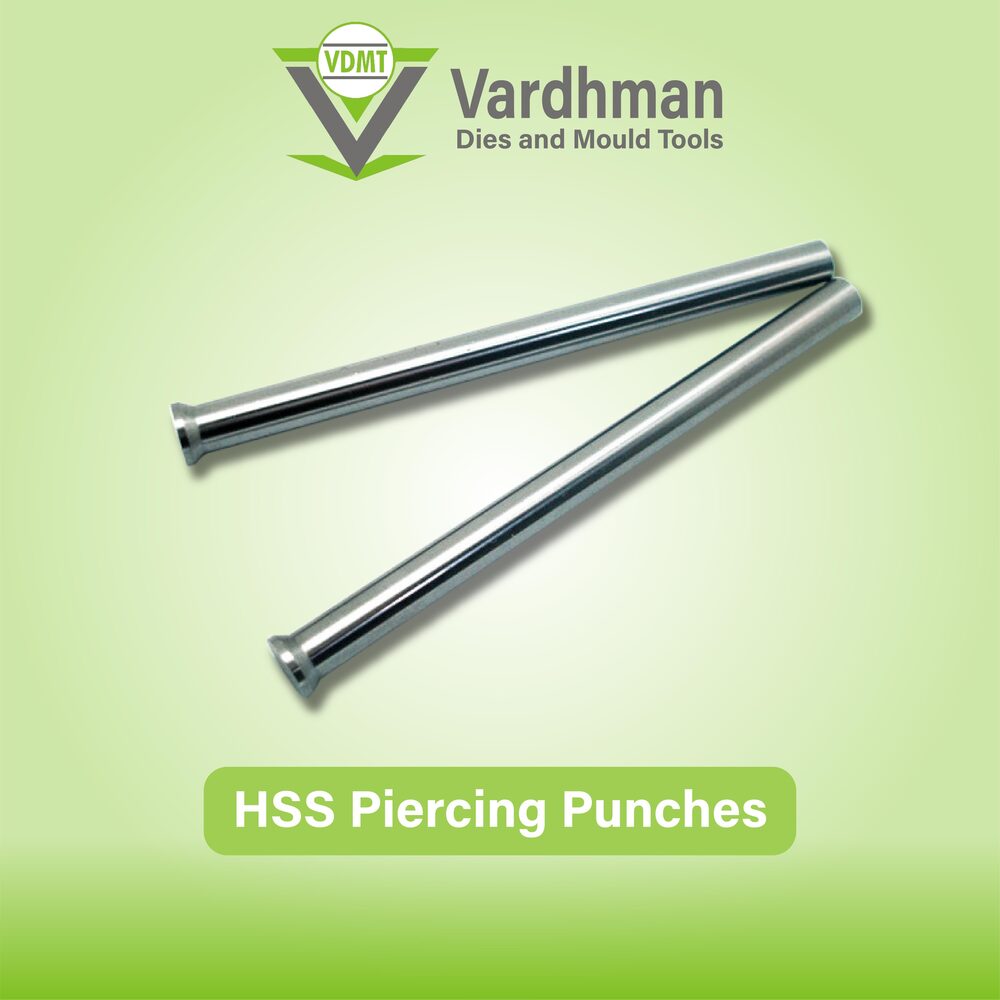

Industrial Piercing Punches

Product Details:

- Core Material HSS M2 - M42- M35

- Material Steel

- Size 0.9 - 6 mm in step of 0.1 mm

- Product Type Industrial Piercing Punches

- Color Silver

- Width 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Length 50, 70, 80, 100 mm Millimeter (mm)

- Click to View more

Industrial Piercing Punches Price And Quantity

- 50 , , Unit

Industrial Piercing Punches Product Specifications

- 0.9 - 6 mm in step of 0.1 mm

- Steel

- HSS M2 - M42- M35

- 50, 70, 80, 100 mm Millimeter (mm)

- 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Industrial Piercing Punches

- Silver

Industrial Piercing Punches Trade Information

- 1000 , , Unit Per Week

- 7 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

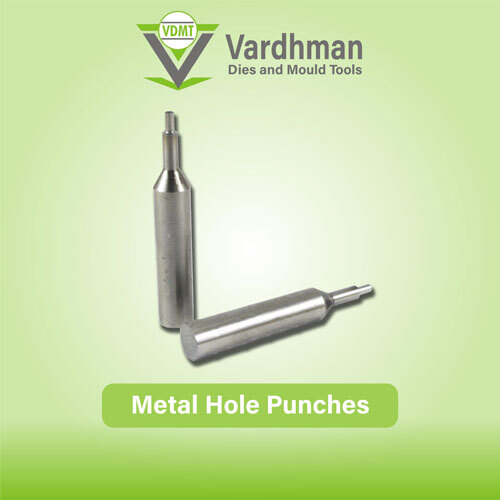

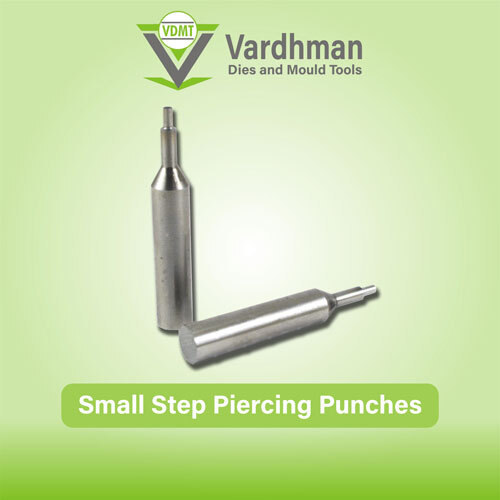

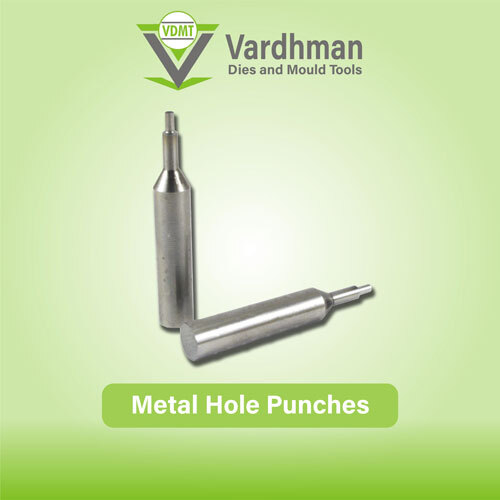

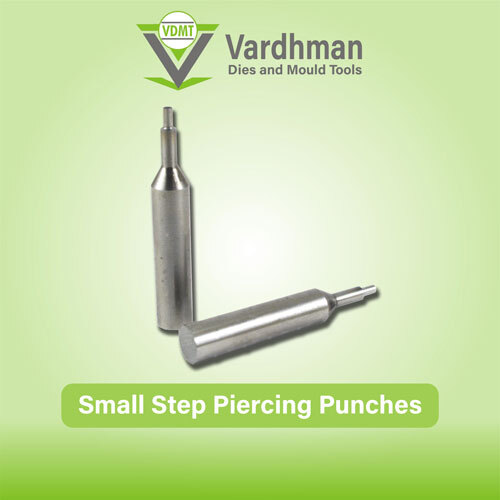

Industrial Piercing Punches are robust tools engineered for high-performance punching applications in heavy-duty manufacturing environments. These punches are designed to pierce holes or shapes with precision and consistency in various materials such as metals, alloys, plastics, and composites. Commonly used in industries like automotive, aerospace, metal fabrication, and electronics, they play a crucial role in enhancing productivity and maintaining quality standards in large-scale production processes.

Key Features of Industrial Piercing Punches

-

Durable Construction

- Manufactured from premium-grade materials like high-speed steel (HSS), tungsten carbide, or tool steel to ensure durability and withstand rigorous use.

-

Versatile Design

-

- Available in standard and custom configurations to suit various industrial requirements.

-

Surface Treatments

- Coated with wear-resistant materials like Titanium Nitride (TiN) or Titanium Carbonitride (TiCN) for extended tool life and reduced friction.

-

Wide Compatibility

- Suitable for use in a variety of punching machines, presses, and die setups.

Applications of Industrial Piercing Punches

-

Automotive Manufacturing

- Creating precise holes or slots in vehicle parts such as frames, panels, and engine components.

-

Metal Fabrication

- Used in cutting or shaping sheet metal for industrial equipment, enclosures, or construction materials.

-

Aerospace Industry

- High-precision punches for lightweight and durable aerospace components.

-

Electrical and Electronics

- Piercing holes or cutouts in metal and plastic parts for circuit boards and enclosures.

-

Packaging Industry

- Punches designed for perforation or hole-punching in packaging materials.

Advantages of Industrial Piercing Punches

-

High Efficiency

- Ensures consistent and reliable punching performance even in high-volume production.

-

Enhanced Longevity

- Durable materials and protective coatings extend tool life, reducing downtime.

-

Customizable Solutions

- Designed to meet specific industrial requirements, ensuring optimal performance.

-

Cost-Effective

- Reduces material wastage and enhances productivity, minimizing operational costs.

-

Easy Integration

- Compatible with various industrial machinery for seamless functionality.

Custom Size Options for Varied Applications

These punches are available in standard widths (50, 70, 80, 100 mm) and can also be tailored to specific requirements. Lengths match the width options, while size increments of 0.1 mm from 0.9 mm to 6 mm provide exceptional flexibility for custom projects and specialized needs.

Premium Materials for Enhanced Durability

Constructed from top-grade HSS M2, M42, and M35 cores, and finished in corrosion-resistant silver steel, our piercing punches deliver long-term stability, sharpness retention, and minimal weareven under heavy-duty, industrial conditions.

Wide Industrial Reach Across India

As a trusted exporter, manufacturer, supplier, and trader, we supply industrial piercing punches to a diverse client base throughout India. We cater to metal fabrication, automotive, and engineering sectors, ensuring consistent product availability and support.

FAQs of Industrial Piercing Punches:

Q: How are the sizes of industrial piercing punches customized?

A: We offer standard sizes from 0.9 mm to 6 mm, increasing in 0.1 mm steps, and allow customization in both width (50-100 mm) and length (50-100 mm) to match unique industrial specifications.Q: What materials are used in the manufacturing of these piercing punches?

A: Our punches utilize high-speed steel (HSS) grades M2, M42, and M35 as the core material, paired with durable steel construction and a silver finish to enhance performance and longevity.Q: Where can these industrial piercing punches be utilized?

A: These punches are ideal for use in metalworking, fabrication, automotive manufacturing, sheet metal industries, and other sectors where precise piercing operations are essential.Q: What is the process for ordering customized punches?

A: To order customized punches, you can specify your required width, length, and size. Our team will then manufacture the punches according to your precise technical requirements and deliver across India.Q: What benefits come from using HSS M2, M42, or M35 core materials?

A: HSS M2, M42, and M35 offer superior hardness, resistance to wear, and excellent heat tolerance, ensuring that our piercing punches maintain optimal sharpness and operational efficiency under demanding conditions.Q: When should industrial piercing punches be replaced?

A: Punches should be replaced when noticeable wear, chipping, or reduced accuracy occurconditions more likely to arise after extended, intensive use. Regular maintenance can prolong their service life.Q: What advantages does your company offer as an exporter and supplier in India?

A: As an experienced exporter, manufacturer, and supplier, we ensure reliable supply chains, stringent quality control, and responsive support, making us a preferred partner for industrial tooling across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free