Call Us

08045479560

Recycling Insert

250 INR/Unit

Product Details:

- Core Material SUS - 420

- Mould Base Mould base

- Usage Industries

- Material Aluminum

- Size Surface Finish: 0.1 micron -.04 micron

- Product Type Recycling Insert

- Color Silver

- Click to View more

X

Recycling Insert Price And Quantity

- 20 Unit

- 250 INR/Unit

Recycling Insert Product Specifications

- Mould base

- 1 year

- Silver

- SUS - 420

- Recycling Insert

- 500- 1000 mm Millimeter (mm)

- Aluminum

- Surface Finish: 0.1 micron -.04 micron

- Industries

Recycling Insert Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Week

- 7 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

The Recycling Insert is a key component in modern manufacturing, providing an innovative solution for recycling materials and enhancing the efficiency of moulding processes. At Vardhman Dies & Mould Tools, we specialize in crafting high-quality recycling inserts that are designed to facilitate efficient recycling of raw materials in the moulding and tooling industries.

Key Features :

- Durable Construction: Made from high-grade materials, recycling inserts are built to withstand high pressures and harsh conditions, ensuring long-lasting performance even under demanding environments.

- Easy Integration: These inserts are easy to integrate into existing moulds, helping streamline the recycling process without the need for additional complex machinery.

- Cost-Effective: By enabling the reuse of raw materials, recycling inserts help reduce waste, lower production costs, and promote sustainable manufacturing practices.

- Enhanced Efficiency: Designed to optimize the recycling of plastic or metal waste, the inserts reduce downtime and ensure a smooth recycling process within the production cycle.

- Environmentally Friendly: Recycling inserts promote sustainability by minimizing waste and reducing the need for new raw materials, making them an eco-friendly solution for modern industries.

Advantages :

- Sustainability: The primary advantage of using recycling inserts is their contribution to environmental sustainability by reducing waste and reusing materials in the manufacturing process.

- Cost Savings: By recycling raw materials and reducing the need to purchase new ones, companies can significantly lower production costs.

- Improved Production Efficiency: Recycling inserts help streamline operations by ensuring waste is efficiently processed and reused, thereby increasing overall productivity.

- Reduced Environmental Impact: Reducing waste and promoting material reuse helps companies meet environmental standards and reduce their carbon footprint.

- Increased Lifespan of Materials: With recycling inserts, raw materials can be recycled multiple times, extending the lifespan of these materials and contributing to resource conservation.

Applications:

- Plastic Injection Moulding: Recycling inserts are widely used in plastic injection moulding to reuse excess plastic, reducing waste and production costs.

- Metal Casting: In metal casting industries, recycling inserts help recover scrap metal, ensuring that valuable materials are reused for future production cycles.

- Automotive Manufacturing: Recycling inserts are used to recover metal and plastic parts in automotive manufacturing, improving material efficiency and reducing waste.

- Consumer Goods Manufacturing: By incorporating recycling inserts, manufacturers in the consumer goods sector can reduce waste and streamline production, making it more eco-friendly.

- Electronics Industry: In electronics, recycling inserts help recover materials such as plastic and metals, which are often recycled into new components, improving sustainability.

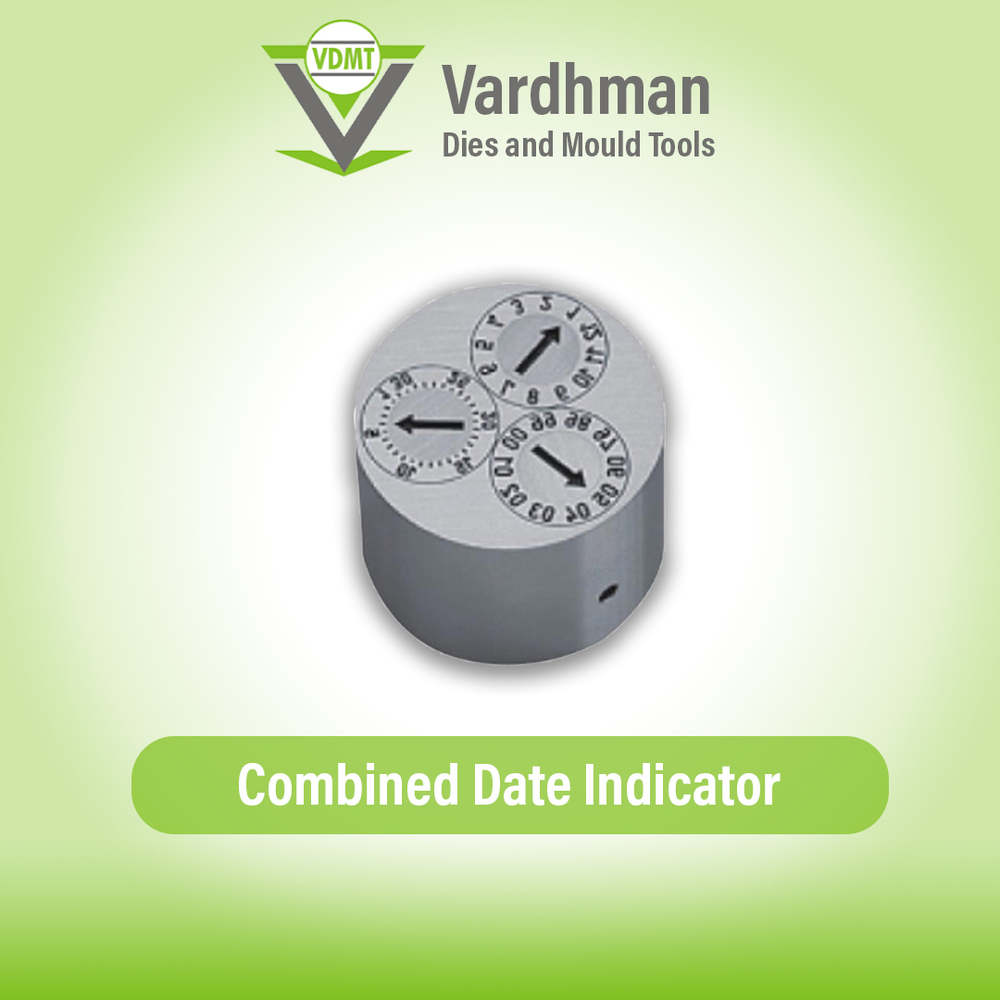

Precision Surface Finish

The Recycling Insert offers an ultra-smooth surface finish ranging from 0.1 to 0.04 microns. This high level of precision ensures seamless integration with industrial mould bases and supports reliable operation throughout extended usage cycles.

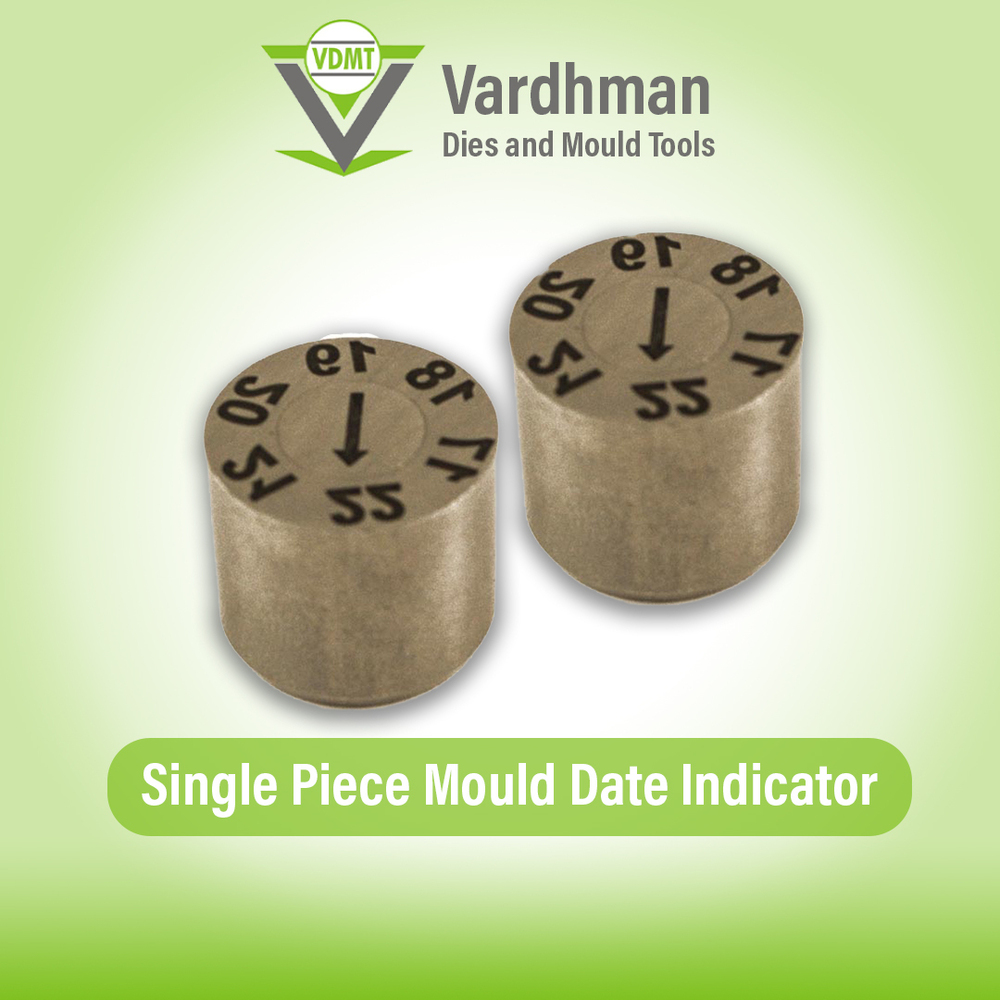

Durable Core Construction

Featuring a SUS-420 core, the insert achieves enhanced hardness and resistance to wear and corrosion. Coupled with an aluminum exterior, it is designed to withstand demanding industrial environments, ensuring long-term dependability.

Versatile Industrial Usage

Designed for industrial settings, this insert is suitable for diverse recycling, manufacturing, and moulding applications. Its customizable length accommodates various specifications, making it a flexible choice for multiple industry groups.

FAQs of Recycling Insert:

Q: How do I install the Recycling Insert in my mould base?

A: Ensure your mould base is compatible with the specified size of the Recycling Insert (5001000 mm). Position the insert carefully within the mould base and secure according to your equipments setup guidelines. If needed, consult your equipment manual or manufacturer support for optimal installation procedures.Q: What materials are used in the Recycling Insert and what are their benefits?

A: The insert combines an outer layer of aluminum with a SUS-420 stainless steel core. Aluminum provides lightweight strength and excellent thermal conductivity, while SUS-420 adds superior hardness and corrosion resistance, resulting in a durable and efficient product.Q: When should the Recycling Insert be replaced or serviced?

A: Routine checks should be performed according to your industrys maintenance schedule. Generally, consider servicing or replacing the insert if you observe any reduction in performance or surface finish quality, or after significant operational cycles, especially when the 1-year warranty period approaches expiration.Q: Where is the Recycling Insert manufactured and supplied from?

A: This Recycling Insert is proudly manufactured, exported, supplied, and traded by reputable producers based in India, serving a wide spectrum of industrial clients domestically and internationally.Q: What process is involved in producing the high surface finish on these inserts?

A: Advanced manufacturing methods and precision finishing techniques are used to achieve a surface finish of 0.10.04 micron. This attention to detail ensures optimal interface with mould bases and maintains consistency in industrial applications.Q: How can the Recycling Insert improve my industrial recycling operations?

A: Using the Recycling Insert enhances operational efficiency by offering durability, superior surface finish, and consistent performance in high-demand industrial recycling settings. Its robust core and resilient exterior extend equipment life while maintaining process quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese