Call Us

08045479560

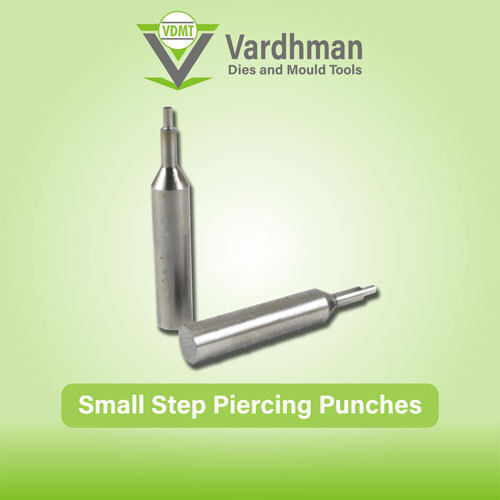

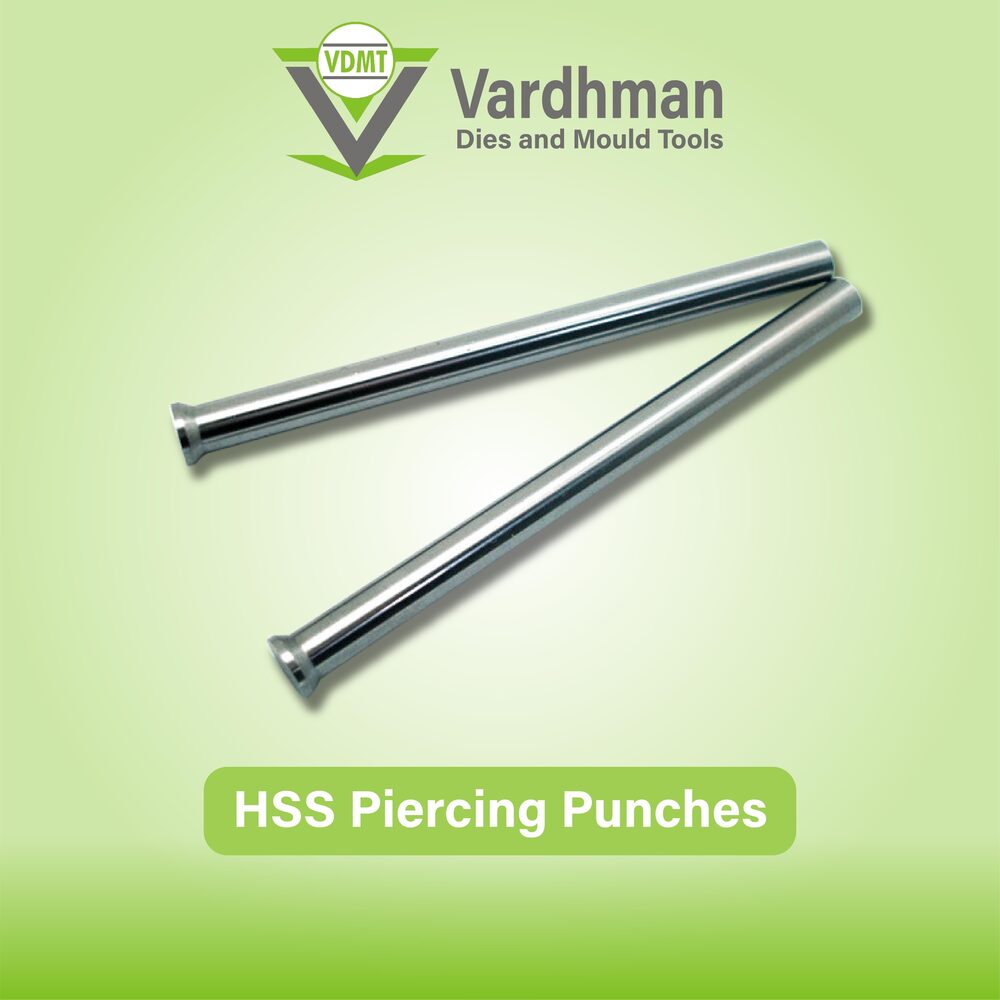

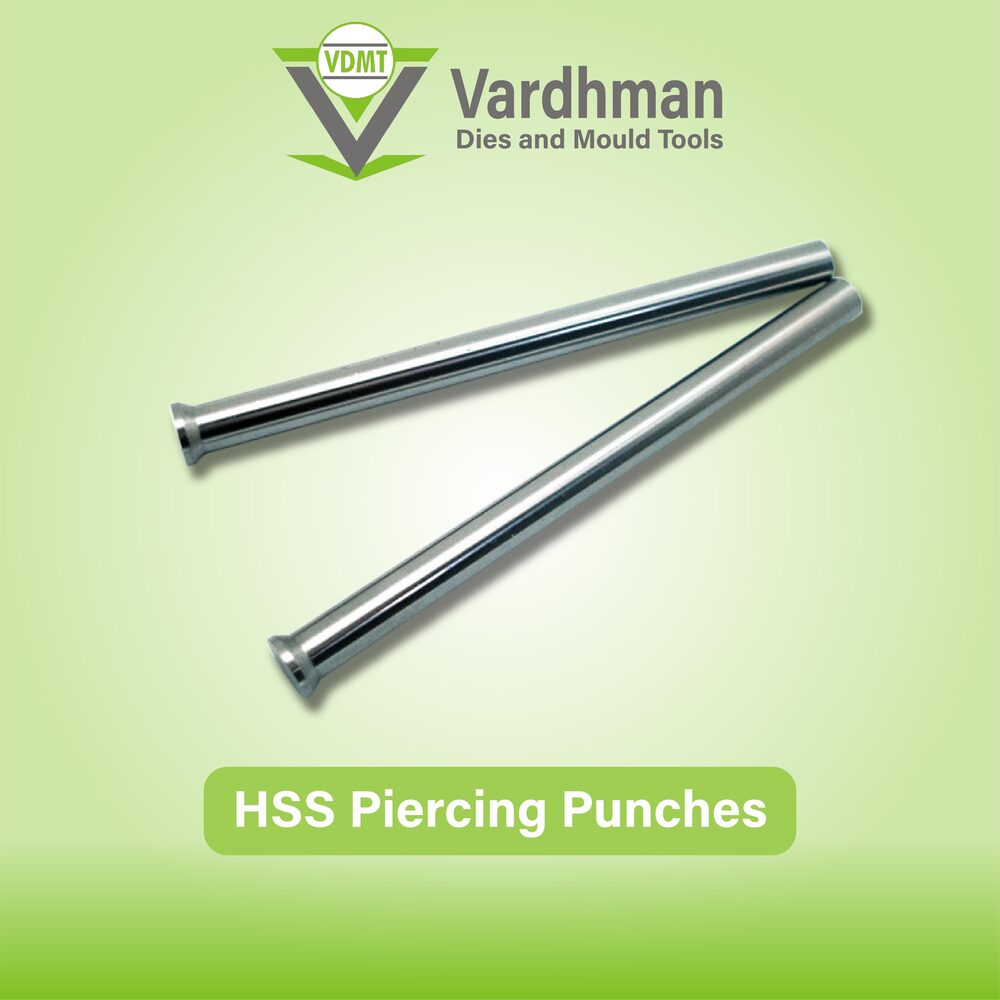

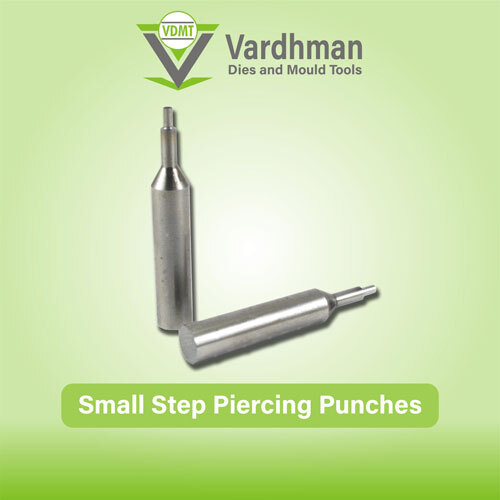

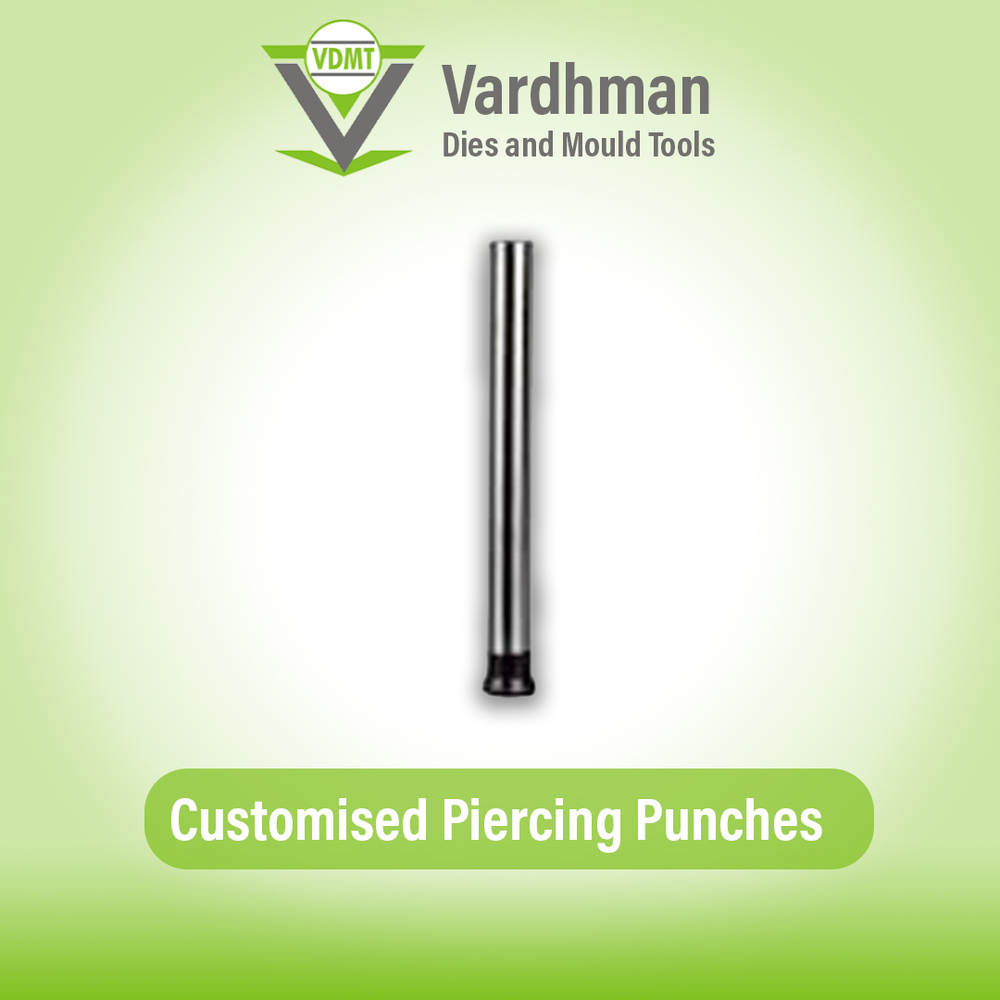

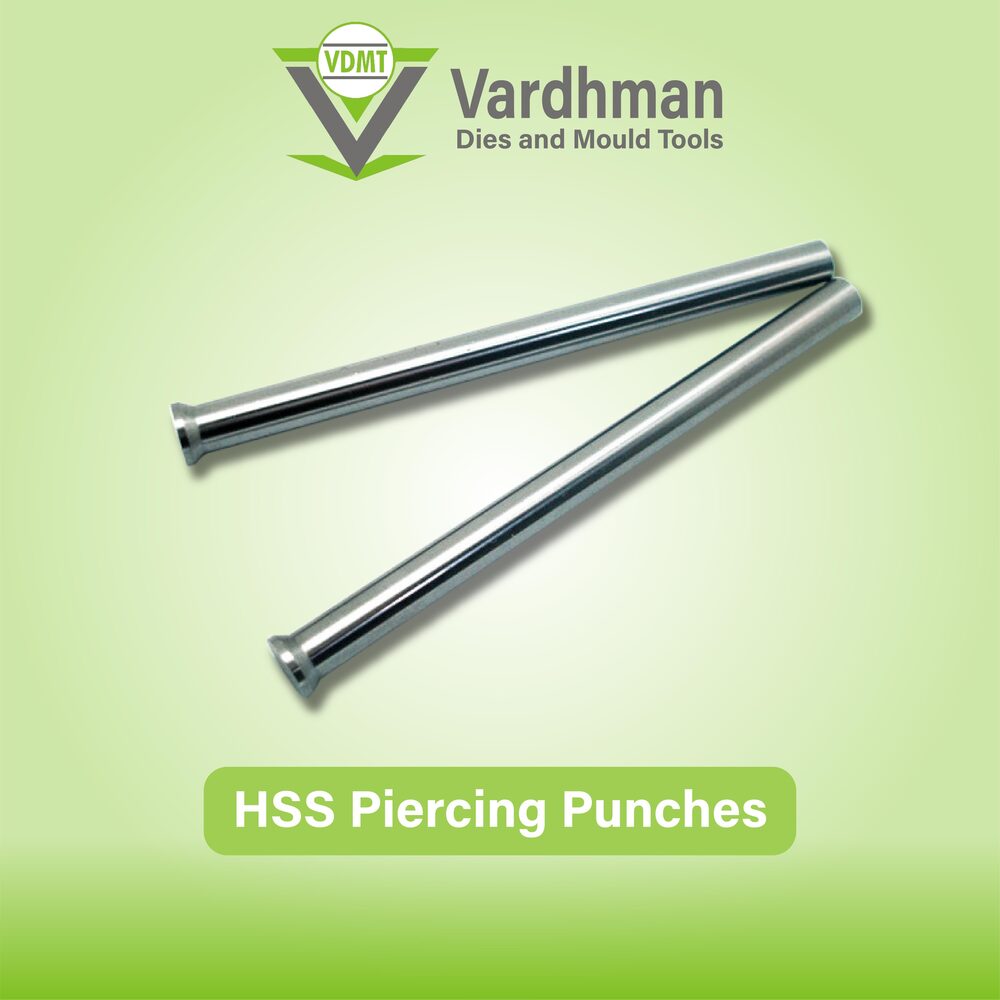

Round Head Punches

Product Details:

- Length 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Core Material HSS M2 M42- M35

- Mould Base Mould base

- Size Surface Finish: 0.2 micron -.04 micron

- Usage Engineering industry

- Product Type Round Punches

- Shaping Mode Punching Mould

- Click to View more

Round Head Punches Price And Quantity

- 300.00 INR/Piece

- 25 Piece

Round Head Punches Product Specifications

- Round Punches

- Punching Mould

- Engineering industry

- Mould base

- Surface Finish: 0.2 micron -.04 micron

- 1 year

- 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- HSS M2 M42- M35

Round Head Punches Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Piece Per Month

- 7 Days

- Carton packaging / As per clients requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

Round Punches are essential tools in manufacturing and machining processes, designed to create precise, round holes or indentations in materials like metal, plastic, leather, or other industrial materials. These punches are widely used in industries such as automotive, aerospace, construction, and metalworking.

-

High Precision:

- Engineered to produce clean, accurate, and perfectly round cuts or holes.

- Tight tolerances ensure repeatable results.

-

Material Composition:

- Typically made from high-speed steel (HSS), carbide, or tool steel for durability and wear resistance.

- Coatings like TiN or DLC can be added to reduce friction and enhance lifespan.

-

Versatile Design:

- Available in various diameters, lengths, and tip configurations to suit different applications.

-

Durability:

- Built to withstand repeated high-pressure impacts in demanding environments.

-

Custom Options:

- Can be customized for specific diameters, lengths, or materials to meet unique application needs.

High Precision:

- Engineered to produce clean, accurate, and perfectly round cuts or holes.

- Tight tolerances ensure repeatable results.

Material Composition:

- Typically made from high-speed steel (HSS), carbide, or tool steel for durability and wear resistance.

- Coatings like TiN or DLC can be added to reduce friction and enhance lifespan.

Versatile Design:

- Available in various diameters, lengths, and tip configurations to suit different applications.

Durability:

- Built to withstand repeated high-pressure impacts in demanding environments.

Custom Options:

- Can be customized for specific diameters, lengths, or materials to meet unique application needs.

Applications of Round Punches:

-

Metalworking:

- Used for punching clean, round holes in sheets, plates, or other metal components.

-

Plastic and Leather Processing:

- Ideal for creating holes in non-metallic materials for various industrial or consumer products.

-

Automotive and Aerospace:

- Employed in the production of components requiring precision holes, such as brackets, mounts, and panels.

-

Construction:

- Used for creating openings in structural components or fastener installations.

Benefits of Using Round Punches:

-

Efficiency:

- Speeds up the production process by quickly and accurately creating holes or indentations.

-

Versatility:

- Suitable for a wide range of materials and applications.

-

Cost-Effectiveness:

- Durable construction ensures a long tool life, reducing replacement costs.

-

Improved Product Quality:

- Produces clean, burr-free holes that reduce post-processing requirements.

Conclusion:

Round Punches are indispensable tools in numerous industrial and commercial operations. Their versatility, durability, and precision make them suitable for a wide range of applications, from metal fabrication to non-metallic material processing. By choosing the right type of round punch and maintaining it properly, manufacturers can achieve superior results, enhance productivity, and minimize costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese