Call Us

08045479560

Square Piercing Punch

50 INR/Pair

Product Details:

- Core Material HSS M2 - M42- M35

- Mould Base Mould base

- Usage Industries

- Material Other

- Size Customized

- Height Surface Finish: 0.3 micron - 0.04 micron Micromete (micron)

- Product Type Square Piercing Punch

- Click to View more

X

Square Piercing Punch Price And Quantity

- 25 Piece

- 50 INR/Pair

Square Piercing Punch Product Specifications

- Other

- Silver

- Square Piercing Punch

- Mould base

- 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Industries

- Customized

- Surface Finish: 0.3 micron - 0.04 micron Micromete (micron)

- HSS M2 - M42- M35

- 1 year

- Dimension 0.2 mm- 50 mm dia Millimeter (mm)

Square Piercing Punch Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Piece Per Month

- 7 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also NSIC and ISO Certified.

Product Description

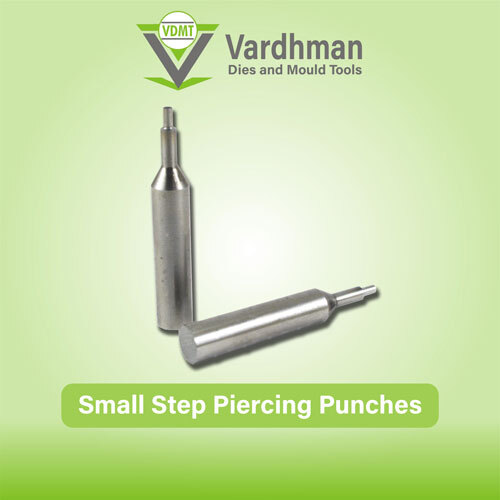

The Square Piercing Punch is a versatile and high-precision tool used extensively in industries like automotive, aerospace, metal fabrication, and electronics. Designed to pierce square holes in various materials, this punch ensures accurate results and superior durability. At Vardhman Dies and Mould Tools, we specialize in manufacturing premium-quality Square Piercing Punches that meet industry standards and cater to diverse client requirements.

Key Features:

- Robust Material:Made from high-grade tool steel or High-Speed Steel (HSS) for exceptional hardness and wear resistance.

- Precision Engineering:Ensures exact dimensions and flawless performance, ideal for high-accuracy applications.

- Customizable Design:Available in various sizes, lengths, and specifications to suit specific punching needs.

- Surface Coating Options:Enhanced with TiN, TiCN, or TiALN coatings for improved durability and reduced friction.

- High Efficiency:Capable of withstanding high loads and repetitive operations without compromising quality

Applications:

- Automotive Industry: Used for fabricating square holes in vehicle components.

- Metal Fabrication: Ideal for creating square holes in sheet metal for various industrial uses.

- Electronics: Perfect for precision punching in delicate and compact electronic components.

- Aerospace: Ensures accuracy and strength in lightweight material punching.

- Packaging Industry: Suitable for creating square perforations in packaging materials.

Benefits:

- High Precision: Guarantees accurate and clean square holes with every punch.

- Durable Performance: Built to handle high-pressure operations, ensuring long tool life.

- Custom Solutions: Tailored to meet specific industry needs and applications.

- Cost-Effective: Reduces downtime and maintenance costs with reliable performance.

- Versatile Usage: Compatible with a wide range of materials, including stainless steel, aluminum, and brass.

Precision Engineering for Industrial Application

The Square Piercing Punch with Mould Base delivers exceptional accuracy for piercing tasks, thanks to its meticulously designed dimensions and superior surface finish. Whether you require a standard or customized size, each punch undergoes rigorous quality control to ensure optimal performance in demanding environments.

Superior Material for Longevity and Efficiency

Manufactured from premium high-speed steel varieties HSS M2, M35, and M42 the punch guarantees extended service life and resilience under high-stress operations. This results in fewer replacements, reduced downtime, and more efficient production cycles for industrial users.

Versatile Fit and Professional Support

With its customizable sizes and diameters ranging from 0.2 mm to 50 mm, this tool can be tailored to fit diverse industrial needs. Whether you are a manufacturer, exporter, supplier, or trader, the product can be adapted to meet your project specifications, supported by expert guidance throughout the procurement process.

FAQs of Square Piercing Punch:

Q: How is the Square Piercing Punch with Mould Base used in industrial applications?

A: It is primarily employed for precise piercing and shaping of metal or other materials during fabrication and manufacturing processes. Its adaptability allows integration into various mould bases for custom or standard production tasks.Q: What materials are used for the core of the Square Piercing Punch, and why?

A: The punch is made from high-speed steel grades such as HSS M2, M35, and M42, selected for their exceptional hardness, wear resistance, and ability to retain sharpness under high temperatures, ensuring reliable long-term use.Q: When should I opt for customized dimensions for my piercing punch?

A: Customization is recommended when standard sizes do not meet your specific production requirements, such as unique thicknesses, diameters, or lengths required for specialized industrial applications.Q: Where are these punching tools manufactured and supplied from?

A: Square Piercing Punches with Mould Bases are manufactured, supplied, and exported across India, ensuring accessibility and support for domestic and international clients alike.Q: What is the process for ordering a square piercing punch with custom specifications?

A: To order a customized punch, you need to provide the preferred length, diameter, core material, and surface finish requirements. The manufacturer will then design and produce the tool to meet your exact needs.Q: What benefits does the high surface finish of 0.3 to 0.04 micron offer?

A: A superior surface finish increases tool life, reduces friction during punching, and results in cleaner, more precise holes or shapes, minimizing the risk of material damage and improving the overall quality of the output.Q: Is there a warranty provided for the Square Piercing Punch, and what does it cover?

A: Yes, the product comes with a one-year warranty, typically covering manufacturing defects or performance issues under normal usage conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese