Call Us

08045479560

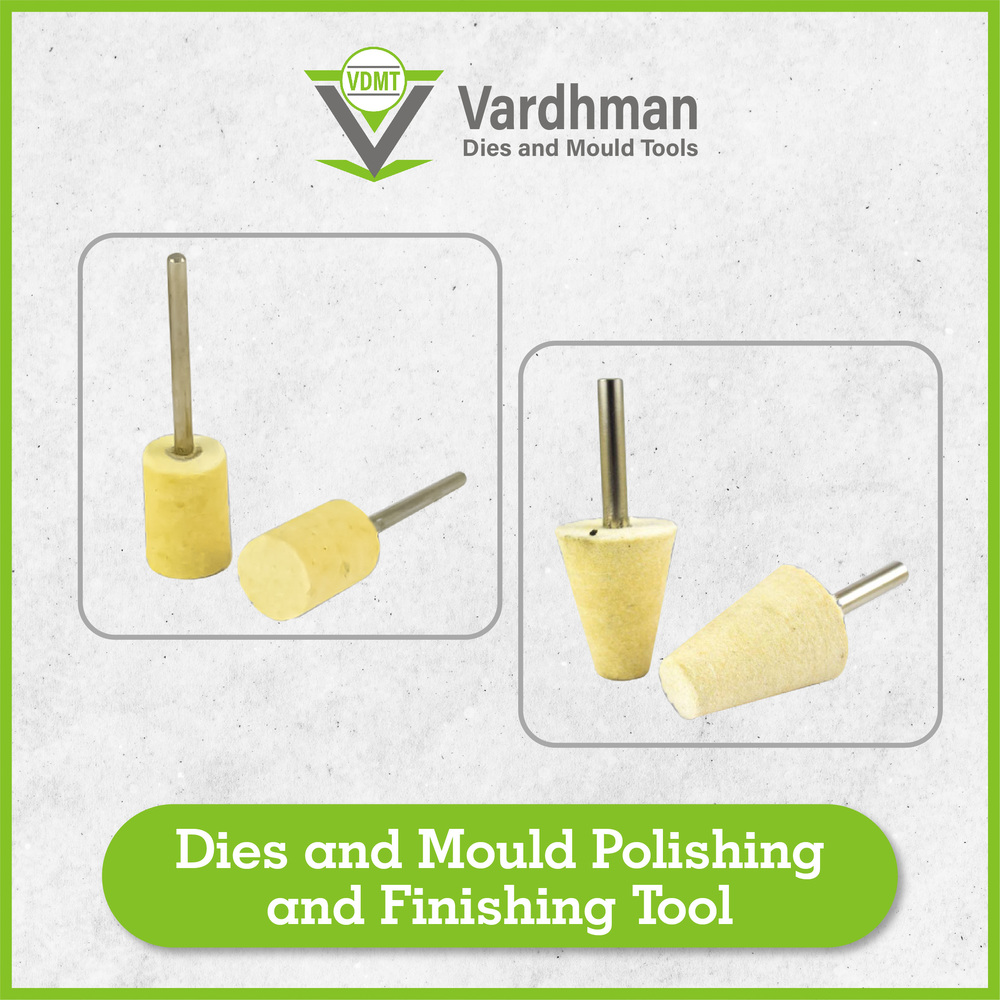

Dies and Mould Polishing and Finishing Tool

40 INR/Unit

Product Details:

- Core Material Steel

- Usage Industries

- Material Steel

- Size Standard

- Color Silvar Stee

- Warranty 1 Year

- Click to View more

X

Dies and Mould Polishing and Finishing Tool Price And Quantity

- 40 INR/Unit

- 20 Unit

Dies and Mould Polishing and Finishing Tool Product Specifications

- Steel

- Standard

- Industries

- Silvar Stee

- Steel

- 1 Year

Dies and Mould Polishing and Finishing Tool Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Week

- 7 Days

- Carton packaging / As per clients requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

Polishing and finishing are essential processes in the manufacturing of dies and molds to ensure precision, efficiency, and superior quality in the final product. At Vardhman Dies & Mould Tools, we offer a wide range of Dies and Mould Polishing and Finishing Tools designed to meet the highest industry standards, ensuring optimal performance and longevity of your dies and molds.

Features of Vardhman Dies and Mould Polishing Tools

- High-Grade Materials: Manufactured from premium-quality materials to withstand wear and ensure durability.

- Precision Engineering: Delivers superior accuracy for intricate detailing and polishing of dies and molds.

- Versatility: Suitable for various applications, including cleaning, deburring, smoothing, and finishing complex surfaces.

- Ergonomic Design: Lightweight and user-friendly tools reduce operator fatigue, enhancing productivity.

Advantages

- Improved Surface Finish: Ensures a flawless and mirror-like surface, enhancing the aesthetic appeal of molded parts.

- Enhanced Mold Life: Proper finishing reduces wear and tear, prolonging the life of dies and molds.

- Increased Efficiency: Reduces production defects, improving product consistency and cycle times.

- Cost-Effective: Minimizes the need for repairs and replacements by maintaining molds in optimal condition.

Applications

- Injection Molding: Used for polishing cavities and cores to achieve a superior finish.

- Die Casting: Helps in refining the surfaces of dies to enhance casting precision.

- Automotive Industry: Polishes molds used for manufacturing automotive components.

- Electronics: Finishes molds for electronic casings and components.

- Medical Devices: Ensures a sterile, smooth surface for medical equipment manufacturing

Robust Design for Maximum Efficiency

Built with premium steel, these polishing and finishing tools are engineered to withstand rigorous industrial use. Their standard size makes them versatile for most dies and mold types, ensuring compatibility and ease of use across different machinery and setups.

Versatile Application in Multiple Industries

Suitable for a wide range of industries, these tools improve the surface finish of molds and dies, contributing to higher product quality. Exporters, manufacturers, suppliers, and traders benefit from enhanced efficiency and reliable performance in their daily operations.

FAQs of Dies and Mould Polishing and Finishing Tool:

Q: How does the Dies and Mould Polishing and Finishing Tool improve industrial processes?

A: This tool is designed to enhance the surface finish of dies and molds, resulting in smoother and more precise final products. By reducing imperfections, it boosts production efficiency and quality control within industrial settings.Q: What materials are used in the construction of this tool?

A: The tool is manufactured using high-grade steel for both the exterior and core materials, ensuring strength, longevity, and reliable performance in demanding conditions.Q: When should I use this polishing and finishing tool?

A: The tool is best used during the final stages of die and mold preparation, prior to assembling or mass-producing components, to achieve optimal surface quality and finish.Q: Where can this tool be sourced in India?

A: This tool is available through established exporters, manufacturers, suppliers, and traders across India who specialize in industrial equipment and finishing solutions.Q: What benefits does the 1-year warranty provide?

A: The 1-year warranty covers any manufacturing defects or performance issues, giving users additional assurance and minimizing potential downtime or replacement costs.Q: Can this tool be used by both large-scale and small-scale industries?

A: Yes, the standard sizing and robust construction make it suitable for a broad range of applications, catering to both large and small industrial operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free