Call Us

08045479560

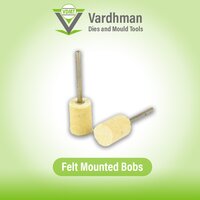

Mandrel Mounted Felt Bobs

38 INR/Unit

Product Details:

- Core Material Steel

- Usage industries

- Material Steel

- Size Standard

- Product Type Mandrel Mounted Felt Bobs

- Color steel , silver

- Click to View more

X

Mandrel Mounted Felt Bobs Price And Quantity

- 38 INR/Unit

- 10 Piece

Mandrel Mounted Felt Bobs Product Specifications

- Standard

- Mandrel Mounted Felt Bobs

- steel , silver

- Steel

- industries

- Steel

Mandrel Mounted Felt Bobs Trade Information

- 1000 Piece Per Week

- 10 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also NSIC and ISO Certified.

Product Description

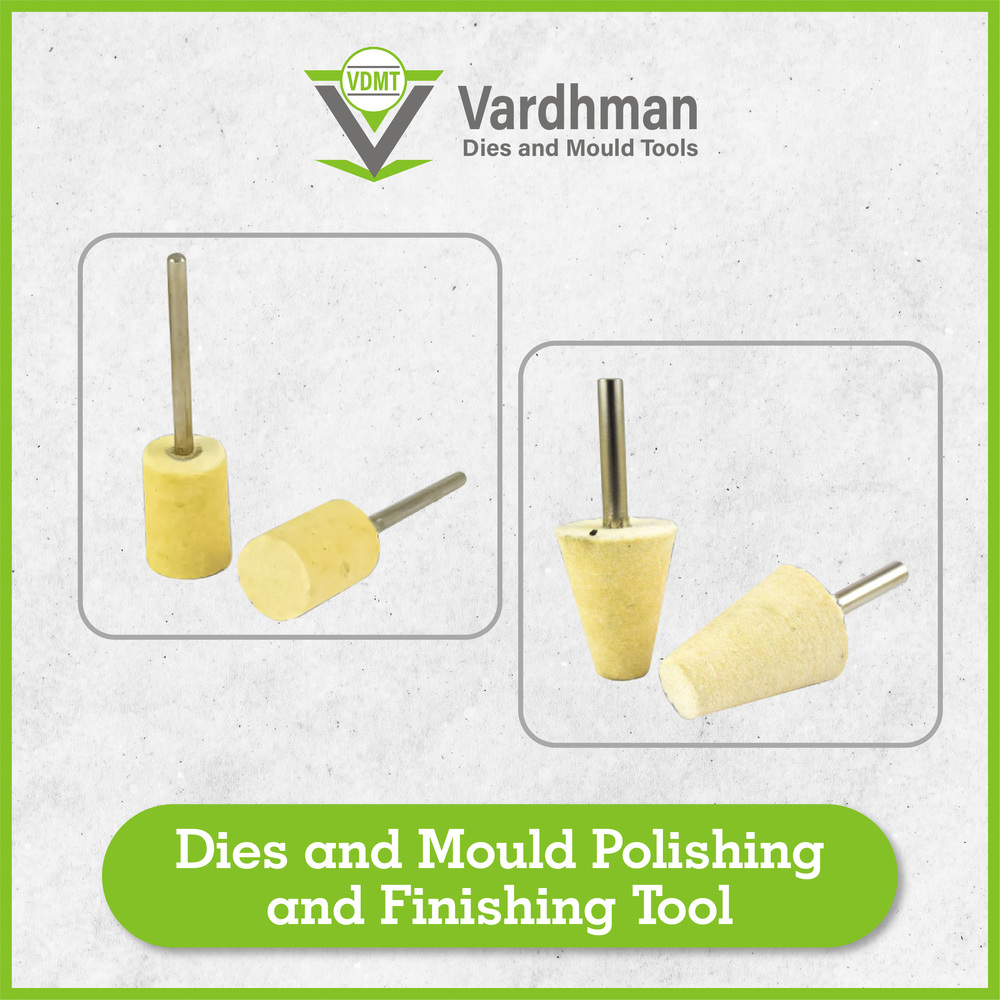

Mandrel Mounted Felt Bobs are versatile and efficient polishing tools designed for precision work across various industries. These tools are widely used for achieving a smooth, polished finish on hard-to-reach areas, intricate surfaces, and delicate components. Vardhman Dies & Mould Tools offers high-quality mandrel-mounted felt bobs engineered for durability, precision, and optimal performance.

Key Features of Mandrel Mounted Felt Bobs

- Premium-Quality Material: Made from tightly compressed wool felt for durability and efficient polishing.

- Mandrel Attachment: Pre-mounted on mandrels for quick and easy installation on rotary tools.

- Wide Range of Shapes: Available in cylindrical, conical, ball-shaped, and bullet-shaped designs to suit various polishing needs.

- Compatibility: Suitable for use with polishing compounds, abrasives, and rouge for versatile applications.

- High Durability: Long-lasting material ensures consistent performance even under high-speed operations.

Advantages

- Precision Finishing: Ideal for polishing detailed surfaces, grooves, and cavities.

- Efficient Performance: Quickly removes scratches, oxidation, and burrs for a mirror-like finish.

- Versatility: Compatible with a variety of materials, including metals, glass, ceramics, and plastics.

- Ease of Use: Lightweight and easy to handle, reducing operator fatigue during extended use.

- Customizable Sizes: Available in different diameters and lengths to match specific project requirements.

Applications

- Metal Polishing: Enhances the surface finish of stainless steel, aluminum, brass, and other metals.

- Jewelry Making: Provides detailed polishing for intricate jewelry designs.

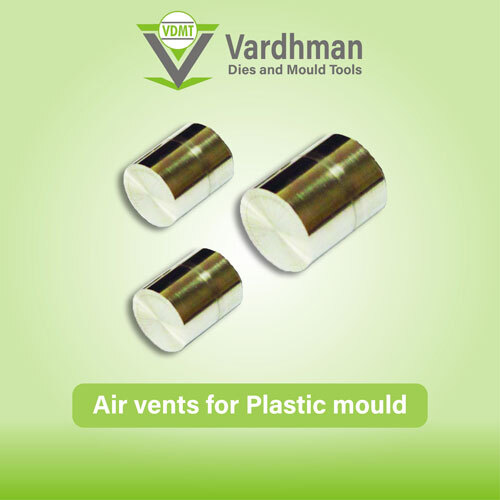

- Mold and Die Maintenance: Maintains the smoothness of dies and molds for improved production quality.

- Automotive Industry: Used for polishing automotive parts and components.

- Glass and Ceramic Work: Refines surfaces without causing damage to delicate materials.

Reliable Industrial Polishing Solutions

Our Mandrel Mounted Felt Bobs feature a sturdy steel core for exceptional stability and durability, making them the preferred choice in varied industrial applications. Suitable for both manual and automated processes, they deliver smooth and precise polishing on metals and other surfaces, reducing the time and effort required for a perfect finish.

Versatility for Multiple Applications

These felt bobs, with their standard sizes and steel-silver finish, are designed to adapt to multiple surface finishing and polishing applications across different industries. Their robust construction ensures longevity, while their universal fit makes them compatible with various polishing tools.

FAQs of Mandrel Mounted Felt Bobs:

Q: How are Mandrel Mounted Felt Bobs with a steel core used in industrial applications?

A: Mandrel Mounted Felt Bobs with a steel core are inserted into power tools or rotary machines to polish, deburr, and finish metal, glass, or plastic surfaces within industrial settings, ensuring a high-quality and refined surface.Q: What is the benefit of choosing felt bobs with a steel core?

A: The steel core enhances structural strength and stability during high-speed operation, reducing vibration and promoting uniform polishing results on various surfaces, significantly improving the efficiency of surface finishing tasks.Q: When should I use these felt bobs in my manufacturing process?

A: These felt bobs are best utilized during the fine finishing or polishing stages after initial shaping or cutting, ensuring smooth and uniform surfaces before final assembly or coating.Q: Where are these Mandrel Mounted Felt Bobs commonly supplied and used?

A: They are widely supplied to manufacturers, repair workshops, and industrial facilities across India, serving sectors like metalworking, jewelry, automotive, and precision engineering.Q: What is the process for using these steel-cored felt bobs?

A: Attach the felt bob to a compatible rotary tool or machine, secure it tightly, and operate at the recommended speed to polish or deburr surfaces. Proper handling ensures both effective results and operator safety.Q: What advantages do these products offer to exporters and suppliers in India?

A: Offering these high-quality, durable tools helps exporters and suppliers meet diverse industrial demands, build client trust, and expand their reach within domestic and international markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free