Call Us

08045479560

X

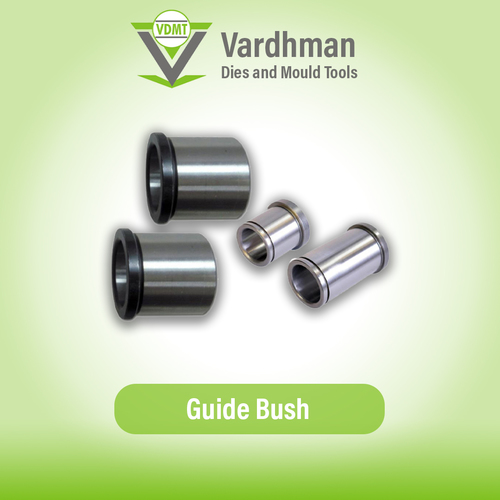

Guide Bush Price And Quantity

- 10

Guide Bush Trade Information

- 10 Days

Product Description

Being a customer-oriented firm, we are engaged in offering a wide range of Guide Bush. This bush is manufactured using optimum grade raw material and sophisticated technology in synchronization with international standards.Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free