Call Us

08045479560

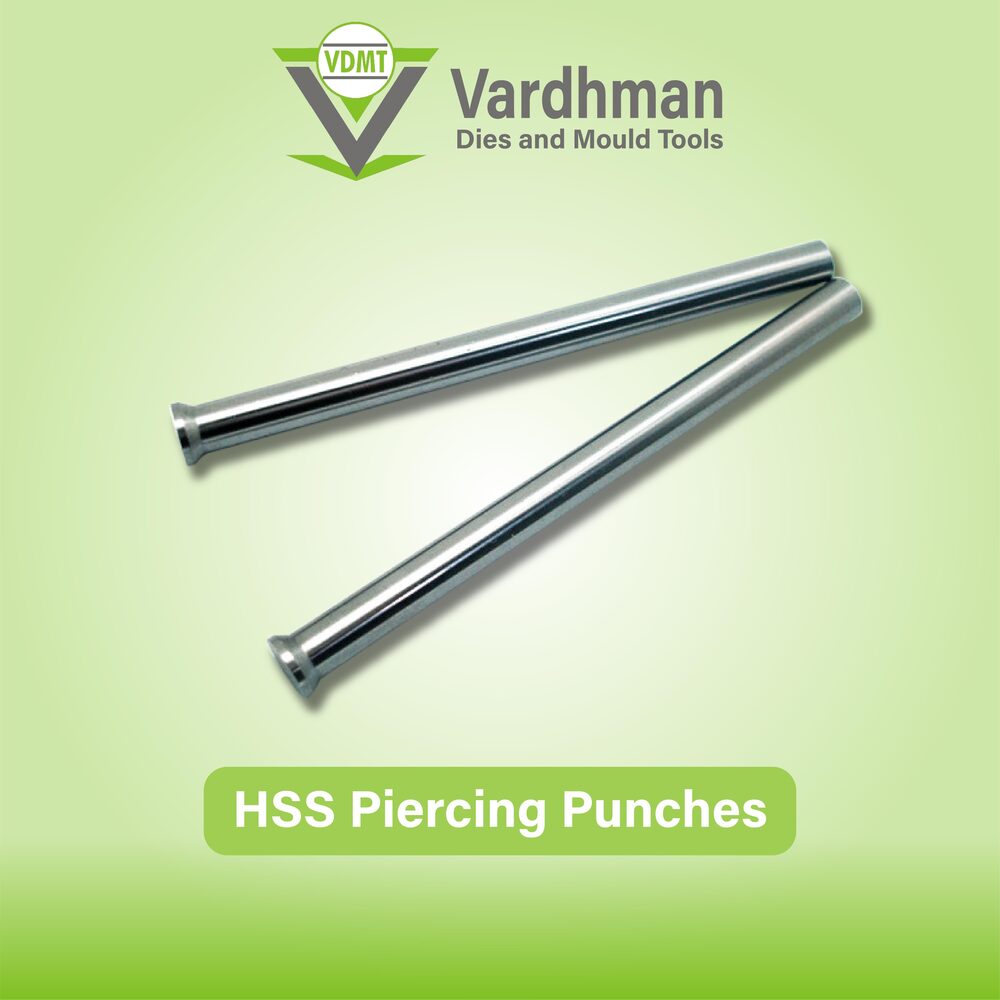

Pilot Punches

Product Details:

- Core Material HSS M2 - M42- M35

- Usage Industries

- Material Steel

- Size Surface Finish: 0.3 micron 0.04 micron

- Product Type Pilot Punches

- Color Silver

- Width Dimension 0.2 mm - 50 mm dia Millimeter (mm)

- Click to View more

Pilot Punches Price And Quantity

- 50 INR/Piece

- 25 , , Unit

Pilot Punches Product Specifications

- Surface Finish: 0.3 micron 0.04 micron

- Steel

- Pilot Punches

- Industries

- 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Silver

- 1 year

- Dimension 0.2 mm - 50 mm dia Millimeter (mm)

- HSS M2 - M42- M35

Pilot Punches Trade Information

- 1000 , , Unit Per Month

- 7 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

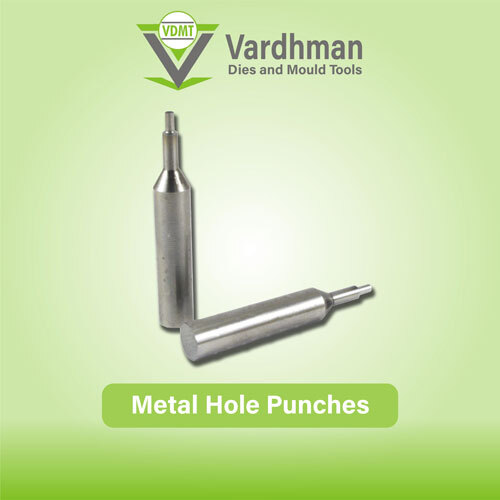

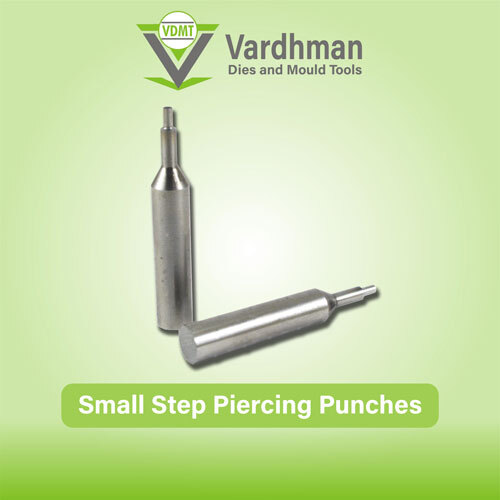

Pilot Punches are precision-engineered tools designed for creating initial pilot holes that guide the subsequent drilling or punching processes. These punches play a vital role in ensuring accuracy and alignment in various applications, including metal fabrication, woodworking, automotive, and industrial manufacturing. Built for durability and high performance, pilot punches are essential for achieving professional-grade results.

Key Features of Pilot Punches

-

Durable Construction

- Manufactured using high-grade materials such as High-Speed Steel (HSS) or alloy steel for extended life and wear resistance.

-

Variety of Sizes

- Available in various diameters and lengths to suit different hole sizes and material thicknesses.

-

Versatile Applications

- Suitable for a wide range of industries and materials, including metals, plastics, and composites.

-

Corrosion Resistance

- Coated with anti-corrosive finishes for enhanced longevity and performance.

Applications of Pilot Punches

-

Metal Fabrication

- Creating pilot holes for precise punching or drilling in metal sheets and plates.

-

Automotive and Aerospace

- Used in making pilot holes for fasteners, rivets, and components.

-

Industrial Manufacturing

- Assists in the alignment of dies and tools for flawless production.

-

Woodworking

- Ensures accurate drilling and reduces the risk of splitting or chipping.

-

Construction

- Ideal for creating guide holes in structural and decorative elements.

Advantages of Pilot Punches

Enhanced Accuracy

-

- Guides drilling or punching tools, reducing errors and improving alignment.

-

Time-Saving

- Eliminates the need for manual measurements and adjustments.

-

Reduced Material Waste

- Ensures precise hole placement, minimizing the risk of rework.

-

Versatility

- Adapts to various materials and industrial requirements.

-

Longevity

- Engineered to withstand repeated use in demanding environments.

-

Superior Material Selection

Designed with robust steel and superior-grade HSS (M2, M35, M42) cores, our Pilot Punches deliver optimal hardness and wear resistance. This choice of material effectively extends longevity and performance, even under demanding industrial conditions.

Precision and Versatility

Featuring diameters from 0.2 mm to 50 mm and unparalleled surface finishes of 0.3 to 0.04 microns, our punches accommodate a variety of industrial tasks. They are available in standard lengths or can be tailored to meet specific requirements, ensuring adaptability.

Assured Quality and Warranty

Each Pilot Punch is meticulously manufactured under strict quality standards and comes with a 1-year warranty. Our products are trusted by industries across India, offering reliable support for your manufacturing and processing needs.

FAQs of Pilot Punches:

Q: How are the Pilot Punches constructed for durability?

A: Our Pilot Punches employ a core of High-Speed Steel (HSS) in grades M2, M35, or M42 encased in robust steel, resulting in exceptional hardness, longevity, and resistance to wear even in high-volume industrial settings.Q: What applications are these Pilot Punches best suited for?

A: These punches are ideal for various industries requiring precise punching, forming, and shaping operations. They serve well in automotive, aerospace, electronics, and general manufacturing environments.Q: When should I consider choosing a specific HSS grade (M2, M35, M42)?

A: Choose M2 for general-purpose work, M35 for moderately tough alloys, and M42 for high-strength or hard-to-machine materials. The selection depends on the specific application and material youre working with.Q: Where are the Pilot Punches manufactured and supplied from?

A: We manufacture, export, and supply our Pilot Punches from India, ensuring prompt delivery and support for clients both domestically and internationally.Q: What is the process behind achieving precise surface finishes on the punches?

A: Our Pilot Punches are processed with advanced grinding and polishing techniques to attain surface finishes between 0.3 micron and 0.04 micron, which enhances performance and tool longevity.Q: How can I benefit from using your Pilot Punches in my production line?

A: Utilizing our Pilot Punches improves precision, reduces downtime, and increases productivity by providing consistent and accurate punching performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free